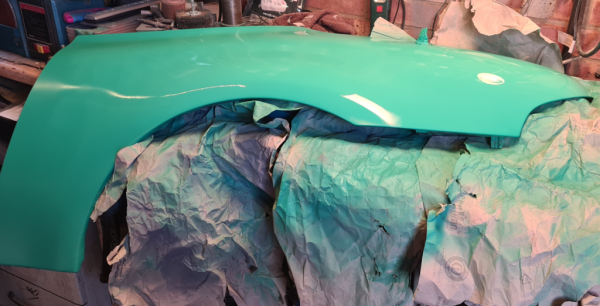

well at the moment it's eyes down on the bodywork..... firstly I always told myself that one day I'd be able to get the car in the garage... and now I have !!

so let's get cracking on those wings !!

bit a bit more Time Team and dug away at what was causing all the rust on the inside.... turns out the stiffening U channel is "sealed" with some body seam sealer. So the any water just sits on this and rots through....I picked some of it out with a screwdriver and it was all surface rust underneath which bled through to the outside paintwork

I used a

finger sander,

dremel wheels and even a

milling bit to get into all the nook and crannies

You can see the holes made my standing water as it can't drain out

More seam sealer picking out... rinse and repeat on the other wing.... and the same symptoms... rusted along this stiffener... I've arrowed what left of the sealer which didn't have rust behind it

Tell tale signs on the front

so I set to with the

flap wheel and the

Dremel with various grit of Dremel sanding wheels.... then I dug out my old friend

POR15 and got a thin wide brush and liberally dosed both wings..... and this is POR 15 dry !... dries rock hard and shiny. I'm actually NOT going to replace that sealer, so there's now a gap between this stiffener and the wing and that's got to help drainage.

Now... onto the rear quarters..... I've always admitted any of my shortcomings , and given this bit would have been too hard for me to weld..... I cheated.... yes... I cheated.... that little patch I managed to dig out? that was put in with body filler?.. I re used it....

but.. this time I fibre glassed it in... made sure the sheets were criss crossed with plenty of resin.... and I have to say, it's now absolutely rock hard. The black is the Kurust I used after grinding off all the rust inside the panel

Then it's on with the

Isopon 38 and I'll let that cure before I start the sanding process....

back to the wings.... and I hit those with

80 grit in a criss cross pattern (

apparently, you never sand in circles) to remove most of the POR15 residue....then I used

knifing putty to fill the small craters caused by the rust

so now I wait for that to all fully cure, before I start the sanding process again...

Isopon set and rubbed down ready for the

dolphin glaze stage

@Lee has probably done about a million of those so can tell you what’s best.