Hi All,

Been a long time lurker on here with sporadic participation.

Well my wife's 'dream car' has been sat in the garage for 3 years. Just didn't need 2 cars and passed last MOT fine (maybe corroded brake pipes on the advisories). But I've always thought after 156,000 miles (we got at 86k) that she needed new bushings, shocks, springs and corrosion treatment.

Mazza's thread inspired me. I promised myself that I had to start it before posting about it particularly as a professional procrastinator. So after a few weeks of buying tools and getting materials etc. I have some stuff to show that I've started and not just put it on axle stands.

The knowledge base is an absolute goldmine of knowledge and how that gave me the confidence in having a go. I've never done up a car before (may have stuck some stripes on back in the day) but I grew up at my local airfield, and on my best mates farm where I liked anything with spanners. Tractors to aeroplanes. Couple of years ago got my pilots license to scratch the itch from growing up helping restore aircraft / cars and refueling the treasure hunt helicopters (back when 'Health & Safety' was left to common sense). Not that I have any but the owner I deemed must have had when I was 13/14. Annabelle Croft's knees...... at head height. Oh Lordy!

Anyway, one eve ventured onto this forum as I do periodically and came across Mazza's thread, and due to COVID tidied the garage within an inch of it's life (even that tub of miscellaneous fixings), and decided that as it was sat there taking up space anyway, then I may as well start it and it'll give me something to do in those moments when you want to do summat.

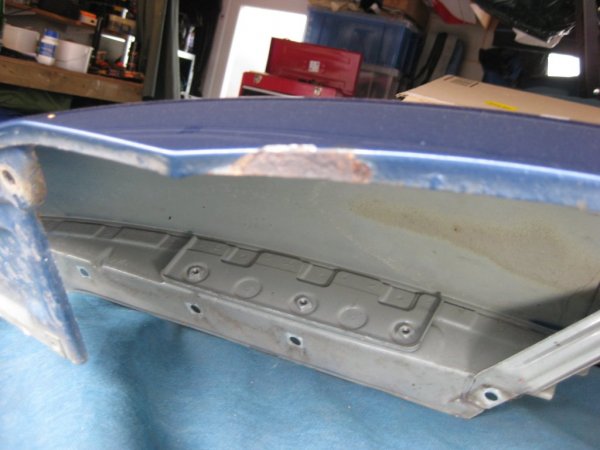

So here is my refurb thread. Cheers Mazza for inspiration. I'm not going for showroom condition but as you can see from some of the surface rust which is low down on the body, I'll 'have a go' and/or keep my eye out for better 2nd hand panels. Even the cills I may experiment with the welder as they are past it really, but the price of 'less' rusty 2nd hand cills make it worth a go. The finish is low down and not as noticeable.

I've already Bilt Hamber'd one inner cill but the rest of the pics show the jobs ahead.

Been a long time lurker on here with sporadic participation.

Well my wife's 'dream car' has been sat in the garage for 3 years. Just didn't need 2 cars and passed last MOT fine (maybe corroded brake pipes on the advisories). But I've always thought after 156,000 miles (we got at 86k) that she needed new bushings, shocks, springs and corrosion treatment.

Mazza's thread inspired me. I promised myself that I had to start it before posting about it particularly as a professional procrastinator. So after a few weeks of buying tools and getting materials etc. I have some stuff to show that I've started and not just put it on axle stands.

The knowledge base is an absolute goldmine of knowledge and how that gave me the confidence in having a go. I've never done up a car before (may have stuck some stripes on back in the day) but I grew up at my local airfield, and on my best mates farm where I liked anything with spanners. Tractors to aeroplanes. Couple of years ago got my pilots license to scratch the itch from growing up helping restore aircraft / cars and refueling the treasure hunt helicopters (back when 'Health & Safety' was left to common sense). Not that I have any but the owner I deemed must have had when I was 13/14. Annabelle Croft's knees...... at head height. Oh Lordy!

Anyway, one eve ventured onto this forum as I do periodically and came across Mazza's thread, and due to COVID tidied the garage within an inch of it's life (even that tub of miscellaneous fixings), and decided that as it was sat there taking up space anyway, then I may as well start it and it'll give me something to do in those moments when you want to do summat.

So here is my refurb thread. Cheers Mazza for inspiration. I'm not going for showroom condition but as you can see from some of the surface rust which is low down on the body, I'll 'have a go' and/or keep my eye out for better 2nd hand panels. Even the cills I may experiment with the welder as they are past it really, but the price of 'less' rusty 2nd hand cills make it worth a go. The finish is low down and not as noticeable.

I've already Bilt Hamber'd one inner cill but the rest of the pics show the jobs ahead.

Attachments

-

157.2 KB Views: 165

-

148.6 KB Views: 167

-

140.9 KB Views: 169

-

61.9 KB Views: 172

-

83.1 KB Views: 163

-

125.2 KB Views: 161

-

137 KB Views: 166

-

117.8 KB Views: 161

-

118.3 KB Views: 159

-

99.5 KB Views: 164

-

58.4 KB Views: 145

-

53.2 KB Views: 159

-

149 KB Views: 152

-

117 KB Views: 149

-

115.2 KB Views: 155

-

135.3 KB Views: 159

-

224 KB Views: 153

-

120.4 KB Views: 145

Last edited: