Yeah, but you did it for a living! I’m just an amateur.

Seemed like a good idea at the time!

- Thread starter IainP

- Start date

When I was working in the offshore oil & gas industry, I used to 'borrow' this, it is a coppercoat compound used on the threads on the drill pipe, casing and tubing etc.I got through a lot of half tins at work . . . . . .

Tony.

Anything that lets things come apart that are meant to, I’m all for it.

After attacking that swing arm, I put it to one side and started on the other. I really don’t know what’s in that Screwfix paint stripper, but for goodness sake don’t put it anywhere near the Z3 arms. It does bugger all except make the coatings harder to remove and the arms rustier. Then I noticed the first arm was wet, except it wasn’t, it was sticky. Right at the really shitty looking metal. I cleaned it left it overnight and it was sticky again. Feck. I have one of those pin hole snake cam things, would it connect to my phone, or pc, no it bloody won’t. Ordered some mini cutting discs because the arm was clearly leaking here.

Chopped a chunk out, it had gone completely through at just a pinhole.

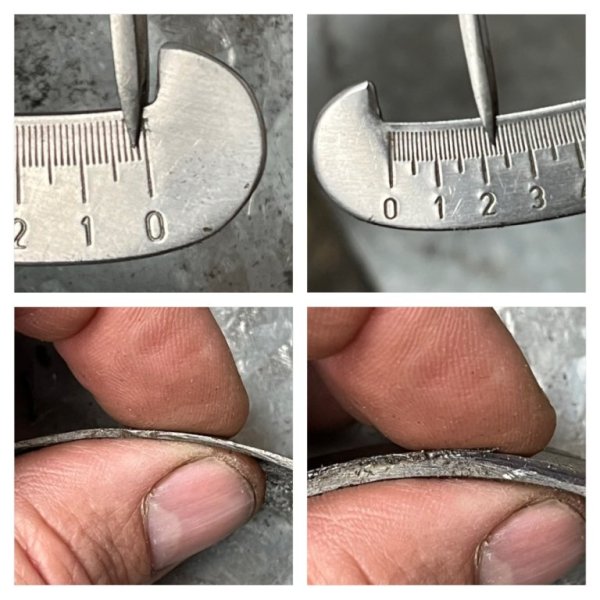

It was really thin though, down to 0.2mm from 2.3mm , I assume it was 3mm before it was pressed.

Cut a piece of 2mm steel and set about making a double curvature repair section. Took me an hour to get it damn near bang on, then another half hour to make it perfect.

Welded it in with zap and chill, ground the weld with Roloc discs.

Since there’s such controversy around weld repairs at the moment, I wanted it absolutely spot on, so yeah I was quite prepared to spend whatever time it required to make the fitment as tight as possible.

Repair, what repair?

Just to prove it, this was what I cut out.

Need to give it a good blast with waxoyl. First I’m going to chop off the screw threads and weld on stainless self tappers.

Chopped a chunk out, it had gone completely through at just a pinhole.

It was really thin though, down to 0.2mm from 2.3mm , I assume it was 3mm before it was pressed.

Cut a piece of 2mm steel and set about making a double curvature repair section. Took me an hour to get it damn near bang on, then another half hour to make it perfect.

Welded it in with zap and chill, ground the weld with Roloc discs.

Since there’s such controversy around weld repairs at the moment, I wanted it absolutely spot on, so yeah I was quite prepared to spend whatever time it required to make the fitment as tight as possible.

Repair, what repair?

Just to prove it, this was what I cut out.

Need to give it a good blast with waxoyl. First I’m going to chop off the screw threads and weld on stainless self tappers.

Nice repair, to protect the inside take the bung out and spray in some lanolin rust preventer or your preferred choice. I was suprised when I removed my bungs doing my refurb with the stinky gunk that shot out, must have been done under pressure.

Cheers, with all the stories circulating about welding and ‘modification’ drawing the ire of dvla, I wanted nothing obviously repaired, even though I plan on adding reinforcement to the rear section, they’ll also look “professional/factory”. It’ll be flooded with waxoyl when finished, I use a schutz gun at about 60psi.

There’s always pressure, it’s due to the volatility of the chemicals in the wax or whatever is used.

There’s always pressure, it’s due to the volatility of the chemicals in the wax or whatever is used.

Since I can’t get any sleep on the bus home tonight, I have some time to update this.

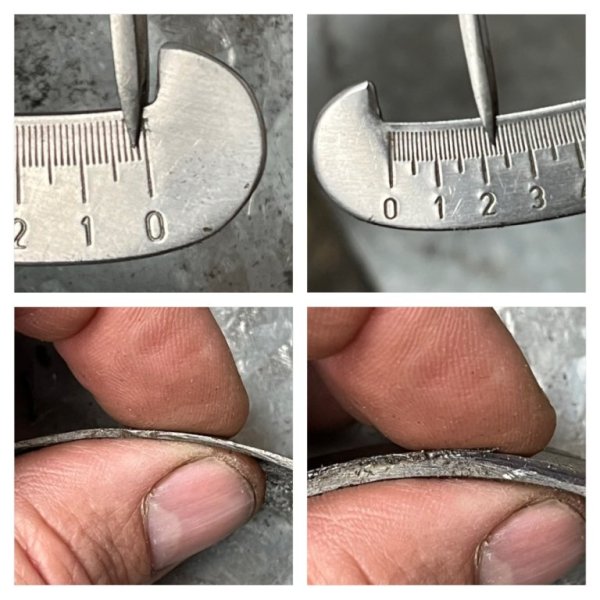

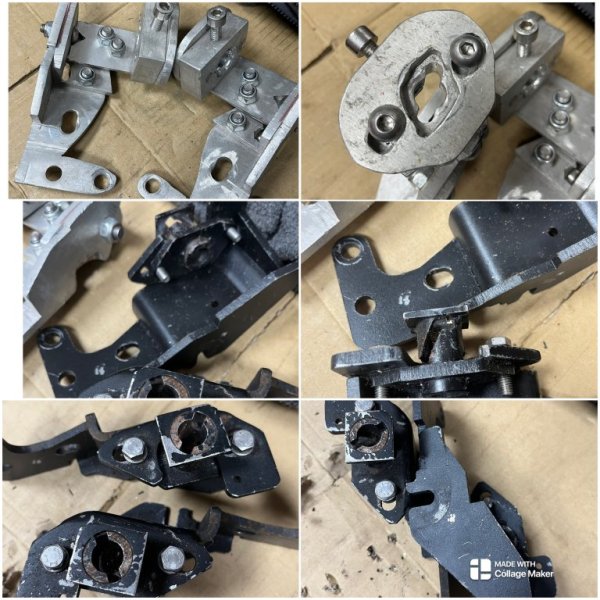

After reading in Pingu’s thread about bent anti roll bar mounts, I checked mine, not bent much, but I straightened and reinforced them.

Zinc galvanising spray, red primer, grey primer, then three coats of Hammerite.

Removed the bung and added 2 syringes of Waxoyl.

Poly bushes

Pressed in new bearings, added new back plates with all the hardware that was zinc sprayed and lacquered. Had to remove some of the paint and then recoat.

The brake pipe brackets cleaned up, but were heavily pitted, so I remade them in stainless steel.

At this point I found I’d made a mistake, when I added the reinforcement to the damper mount I’d dimple die’d it with a hole for the brake pipe to pass through. Forgot the thickness of the paint! Had to cut some away, so glued the grommet in place to seal the metal.

Added the arms to the beam and lifted it in place. Another problem, the camber bolts to adjust the arms are too long. Off again, shortened them and removed a section of the top hat washer thing for better access.

The lightweight flywheel arrived.

If I’d had any notion this year would have gone so slow, I’d have pulled the motor, balanced the pistons and rods, dowelled the flywheel and had it balanced to the crank, though I’d have needed a clutch cover, which I still haven’t got. The flywheel and 6 speed will need to be a spring job.

Made a much stiffer lower brace for my sons Touring a few years ago, I had a design in my head for the Z . Steel tube, bushed, sealed ends, welded in place with actual shanked bolts. Wiggle room . . . None. Two fishmouthed oval bars running either side of the engine, braced with 3mm dimpled sheet. Welded and braced to a big bracket bolted to the crossmember with 6x M8 and 1x M10 set screws.

It Is SOLID.

It did show the engine had dropped.

New engine mounts had the 1mm clearance from the base of the brackets up to 11 mm.

My son has an alloy sump guard spare, it’s seen better days and it’s not a great fit the way I’ve made this bracket.

I may make a Kevlar guard, just for a laugh , and bragging rights.

, and bragging rights.

Added a bracket for the relocated fuel filter, 3mm stainless, total overkill, but it’s fuel lines, I’m not to keen on those vibrating.

Remade the rear carrier bolt in stainless, tube over 6mm threaded rod with a flange nut welded on the end. All polished, just because I could.

The air line for the spare wheel needs replaced, it’s rotten. That’s in Hand.

Both front lollipop bushes were removed and replaced with offset solid M3 bushes. A little silicone grease makes the job a breeze.

Fitted the Mondeo arb brackets.

At the rear I have an 18.5mm bar with poly bushes, I could not get hold of the correct size in poly so squeezed on 18mm with silicone grease. Was a challenge, but it fits. The mounts are boxed.

The ends are 12mm when the paint is removed. 12mm spherical joints are a tight fit, going with those retained by star lock washers, into spherical ball joints on the arms. I think it’ll work, time will tell.

After reading in Pingu’s thread about bent anti roll bar mounts, I checked mine, not bent much, but I straightened and reinforced them.

Zinc galvanising spray, red primer, grey primer, then three coats of Hammerite.

Removed the bung and added 2 syringes of Waxoyl.

Poly bushes

Pressed in new bearings, added new back plates with all the hardware that was zinc sprayed and lacquered. Had to remove some of the paint and then recoat.

The brake pipe brackets cleaned up, but were heavily pitted, so I remade them in stainless steel.

At this point I found I’d made a mistake, when I added the reinforcement to the damper mount I’d dimple die’d it with a hole for the brake pipe to pass through. Forgot the thickness of the paint! Had to cut some away, so glued the grommet in place to seal the metal.

Added the arms to the beam and lifted it in place. Another problem, the camber bolts to adjust the arms are too long. Off again, shortened them and removed a section of the top hat washer thing for better access.

The lightweight flywheel arrived.

If I’d had any notion this year would have gone so slow, I’d have pulled the motor, balanced the pistons and rods, dowelled the flywheel and had it balanced to the crank, though I’d have needed a clutch cover, which I still haven’t got. The flywheel and 6 speed will need to be a spring job.

Made a much stiffer lower brace for my sons Touring a few years ago, I had a design in my head for the Z . Steel tube, bushed, sealed ends, welded in place with actual shanked bolts. Wiggle room . . . None. Two fishmouthed oval bars running either side of the engine, braced with 3mm dimpled sheet. Welded and braced to a big bracket bolted to the crossmember with 6x M8 and 1x M10 set screws.

It Is SOLID.

It did show the engine had dropped.

New engine mounts had the 1mm clearance from the base of the brackets up to 11 mm.

My son has an alloy sump guard spare, it’s seen better days and it’s not a great fit the way I’ve made this bracket.

I may make a Kevlar guard, just for a laugh

Added a bracket for the relocated fuel filter, 3mm stainless, total overkill, but it’s fuel lines, I’m not to keen on those vibrating.

Remade the rear carrier bolt in stainless, tube over 6mm threaded rod with a flange nut welded on the end. All polished, just because I could.

The air line for the spare wheel needs replaced, it’s rotten. That’s in Hand.

Both front lollipop bushes were removed and replaced with offset solid M3 bushes. A little silicone grease makes the job a breeze.

Fitted the Mondeo arb brackets.

At the rear I have an 18.5mm bar with poly bushes, I could not get hold of the correct size in poly so squeezed on 18mm with silicone grease. Was a challenge, but it fits. The mounts are boxed.

The ends are 12mm when the paint is removed. 12mm spherical joints are a tight fit, going with those retained by star lock washers, into spherical ball joints on the arms. I think it’ll work, time will tell.

Last edited:

I wanted to make my own hardtop. I had a friend of a friend who told me the best way to make the buck from a scrap soft top.

Anyway, long story short, he’s a knob, adding resin to a soft top just makes a mess, don’t do it. It’s utterly impossible to get a consistent line round the windows. I’m not showing pictures of how much of a mess, it’s embarrassing. Chopped it back to a frame.

I have an Mx5 rear window, made a composite replica, it’s only slightly smaller than the soft top window and really light.

It’s also heated.

I spent ages lining it up with alloy strip

Version 1, after lots of measuring, it was rubbish. Version 2 was a major improvement, putting the window at a steeper angle gives more clearance for the boot lid.

Not much in it, but it should give more coverage for a better seal.

I was quite literally drilling holes when a Gumtree alert popped on my phone. £500 hardtop only an hour and a half away.

Getting it home was an adventure, only the e82 was available and the road I had to traverse was bumpier than a bumpy thing.

Glad I took a selection of straps, having seen the road in, I used all of them for the drive back. No, it’s not the wrong way round, the other way would be a huge air brake.

It’s sitting on the car at the moment, it’ll be on for the winter. Next summer though I absolutely MUST make my own. I lifted it in place on my own, fairly sure I won’t manage to safely lift it off on my own. That’s non negotiable, so I need something lighter. A lot lighter. I expect the BMW one is solid csm, using carbon and core I should be able to halve the standard weight. Using screws instead of a q/r clamp, feck that. I’ll rip off the shape round the door window frames, then freestyle the rest with the Mx window.

Anyway, long story short, he’s a knob, adding resin to a soft top just makes a mess, don’t do it. It’s utterly impossible to get a consistent line round the windows. I’m not showing pictures of how much of a mess, it’s embarrassing. Chopped it back to a frame.

I have an Mx5 rear window, made a composite replica, it’s only slightly smaller than the soft top window and really light.

It’s also heated.

I spent ages lining it up with alloy strip

Version 1, after lots of measuring, it was rubbish. Version 2 was a major improvement, putting the window at a steeper angle gives more clearance for the boot lid.

Not much in it, but it should give more coverage for a better seal.

I was quite literally drilling holes when a Gumtree alert popped on my phone. £500 hardtop only an hour and a half away.

Getting it home was an adventure, only the e82 was available and the road I had to traverse was bumpier than a bumpy thing.

Glad I took a selection of straps, having seen the road in, I used all of them for the drive back. No, it’s not the wrong way round, the other way would be a huge air brake.

It’s sitting on the car at the moment, it’ll be on for the winter. Next summer though I absolutely MUST make my own. I lifted it in place on my own, fairly sure I won’t manage to safely lift it off on my own. That’s non negotiable, so I need something lighter. A lot lighter. I expect the BMW one is solid csm, using carbon and core I should be able to halve the standard weight. Using screws instead of a q/r clamp, feck that. I’ll rip off the shape round the door window frames, then freestyle the rest with the Mx window.

I can lift it off on my own, just, but it’s a struggle and the chances of dropping it are high.

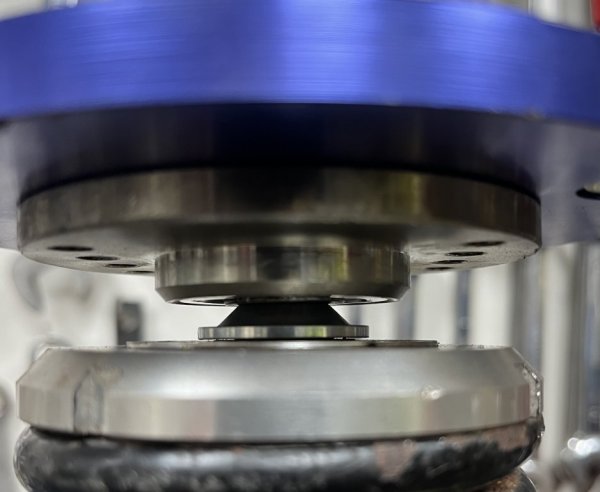

I got these alloy mounts from here, they’re crude and ugly but they’ll hold the top on over the winter.

The proper steel ones came up cheap enough on eBay I bought them to see how different they were. Or how accurate the alloy ones are, or not. “Can you not just copy them?” said my mate at work, scan and print them in carbon. Probably, but I could certainly laser, or plasma cut, the parts and weld them. Project to try next summer. I really need to get this Z moving before swimbo makes me sleep in it.

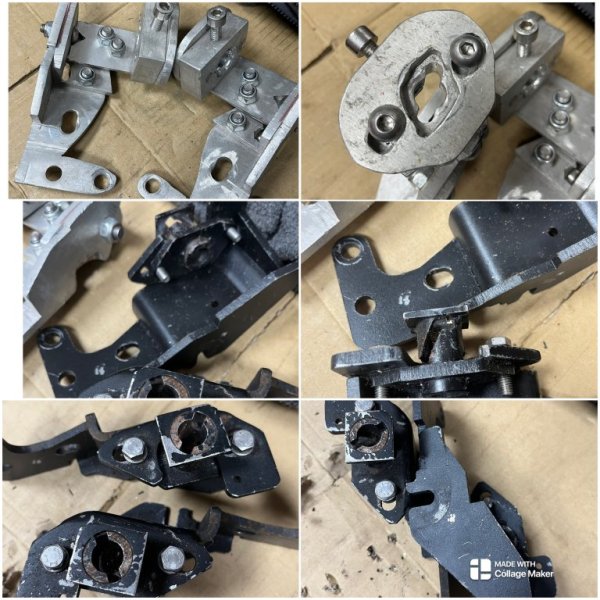

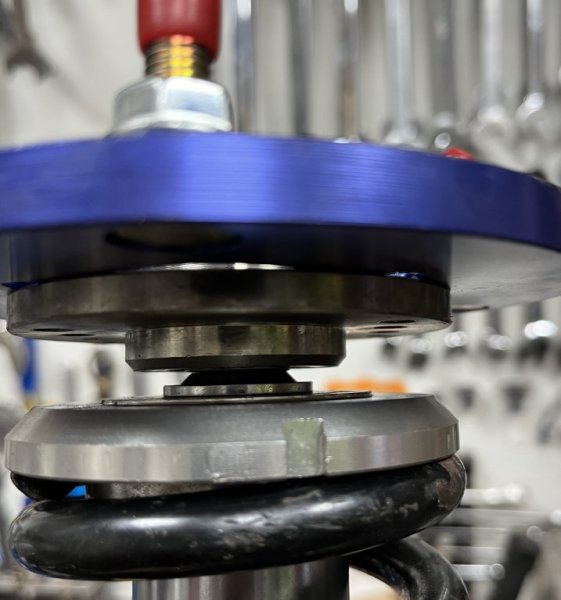

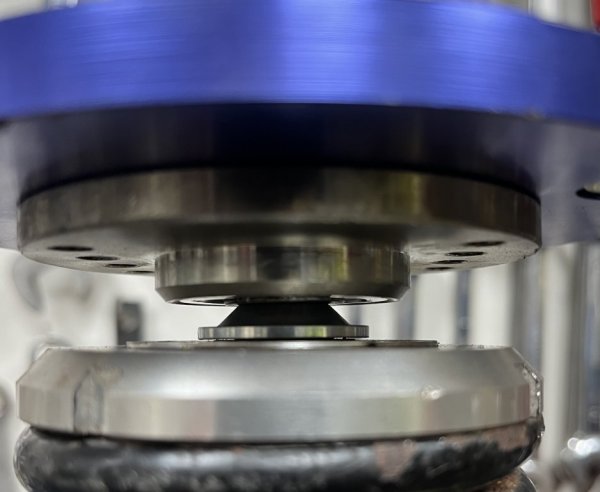

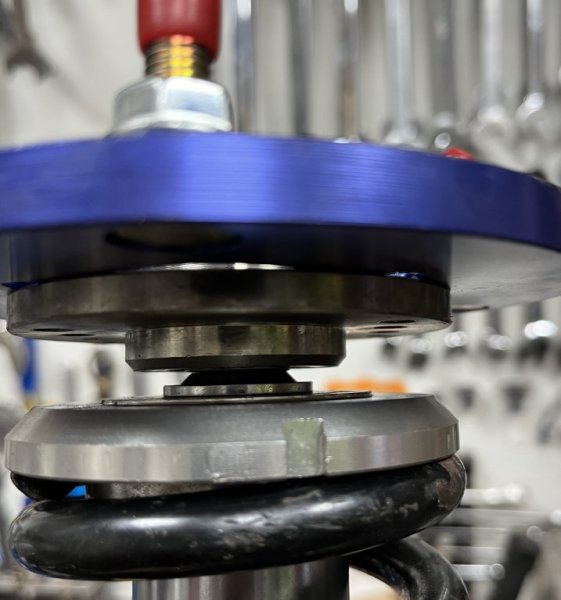

My coilover struts still weren’t welded up and I spotted a pair on eBay, the pics were crap, what the hell, hit buy it now.

Looked a little weird, and one was obviously slightly damaged but useable.

Bottom left pic, that’s not right somehow, why is the cap offset? Because the muppet had the washer stack below the top cap , pic 2, instead of above, pic 3. Pic 4, one leg has some corrosion, thankfully it’s been polished smooth so it doesn’t chew the du bushes in the legs. Big scores at the top of the leg, thankfully it’ll never compress that much they come into play.

Went to fit the top hat bush. They don’t fit. Why? Because the washer stack allowed the top cap to move, it’s bent the stem. Not by much, not even 0.5mm. I resorted to a hammer tap.

That washer is the wrong one! Levered it off, fitted the correct one, and it hits the top mount. Levered that off and hunted up a misalignment spacer.

That does the job, except it doesn’t, the top nut doesn’t engage the nyloc section.

Off again, reduced the height. Sorted.

I may strip it all back down again once I’ve trial fitted them, firstly to chamfer the edge of the washer and secondly, there’s no bracket for the brake line or sensors. If I have sufficient thread space at the desired ride height I could add a bracket on a spare locking ring.

Whatever really, these will do the job to get the thing mobile, getting fed up borrowing all the family cars. I almost bought a Z4 that needed a water pump this week out of shear frustration. I value my nads though.

I got these alloy mounts from here, they’re crude and ugly but they’ll hold the top on over the winter.

The proper steel ones came up cheap enough on eBay I bought them to see how different they were. Or how accurate the alloy ones are, or not. “Can you not just copy them?” said my mate at work, scan and print them in carbon. Probably, but I could certainly laser, or plasma cut, the parts and weld them. Project to try next summer. I really need to get this Z moving before swimbo makes me sleep in it.

My coilover struts still weren’t welded up and I spotted a pair on eBay, the pics were crap, what the hell, hit buy it now.

Looked a little weird, and one was obviously slightly damaged but useable.

Bottom left pic, that’s not right somehow, why is the cap offset? Because the muppet had the washer stack below the top cap , pic 2, instead of above, pic 3. Pic 4, one leg has some corrosion, thankfully it’s been polished smooth so it doesn’t chew the du bushes in the legs. Big scores at the top of the leg, thankfully it’ll never compress that much they come into play.

Went to fit the top hat bush. They don’t fit. Why? Because the washer stack allowed the top cap to move, it’s bent the stem. Not by much, not even 0.5mm. I resorted to a hammer tap.

That washer is the wrong one! Levered it off, fitted the correct one, and it hits the top mount. Levered that off and hunted up a misalignment spacer.

That does the job, except it doesn’t, the top nut doesn’t engage the nyloc section.

Off again, reduced the height. Sorted.

I may strip it all back down again once I’ve trial fitted them, firstly to chamfer the edge of the washer and secondly, there’s no bracket for the brake line or sensors. If I have sufficient thread space at the desired ride height I could add a bracket on a spare locking ring.

Whatever really, these will do the job to get the thing mobile, getting fed up borrowing all the family cars. I almost bought a Z4 that needed a water pump this week out of shear frustration. I value my nads though.

Spent a while on Saturday morn trying to get a new gas cylinder for my welder without success, probably should have made all the calls during the week. None of the Boc suppliers had the size cylinder I want, the Hobbyweld supplier doesn’t stock the big cylinder, the SGS cylinders are only 200bar. Pain in the arse, I need to have a word with Boc and find out the biggest bottle I can get on the Hobby contract.

Couple of hours with the big brush on a bench grinder, and mixture of Roloc disc and stones in a handpiece, had the front uprights back to bare metal. Zinc galvanising spray, four coats of primer and two coats of Lidl finest metal paint, which is actually really good. Hard and extremely smooth with a self levelling glossy surface.

I bought new backplates, though they came painted, and the originals lasted 20 odd years, I scuffed them, 2 coats of red primer, 2 coats of grey, then picked up an old can that had black overspray at the nozzle.

You know what’s coming don’t you, the nozzle had been swapped and it was/is blue!

You know what’s coming don’t you, the nozzle had been swapped and it was/is blue!

I’m pretty sure that’s for an X type Jaaaag

And it’ll need lacquered. But what the hell, I was bored with painting stuff black anyway, hence the grey uprights.

Oh, and I discovered the slip ring is knackered, went to swap it on my son’s car and the ribbon came away from the connector as I touched it. That may have been the problem all along, not the ecu, though that did require a reset t. I’d just given a visual inspection, not checked it for continuity. Stupid. Obviously need another, but I may try and open the connector.

Couple of hours with the big brush on a bench grinder, and mixture of Roloc disc and stones in a handpiece, had the front uprights back to bare metal. Zinc galvanising spray, four coats of primer and two coats of Lidl finest metal paint, which is actually really good. Hard and extremely smooth with a self levelling glossy surface.

I bought new backplates, though they came painted, and the originals lasted 20 odd years, I scuffed them, 2 coats of red primer, 2 coats of grey, then picked up an old can that had black overspray at the nozzle.

I’m pretty sure that’s for an X type Jaaaag

And it’ll need lacquered. But what the hell, I was bored with painting stuff black anyway, hence the grey uprights.

Oh, and I discovered the slip ring is knackered, went to swap it on my son’s car and the ribbon came away from the connector as I touched it. That may have been the problem all along, not the ecu, though that did require a reset t. I’d just given a visual inspection, not checked it for continuity. Stupid. Obviously need another, but I may try and open the connector.

Last edited:

Gotten next to nothing done, a cold turned into a chest infection, that turned into pneumonia and chest pains. So a visit to hospital, beta blockers and blood thinners mean I’m continually cold which will be lovely heading into a Scottish winter. At least until I get a precautionary angiogram. Lovely.

Picked up a spare engine today though. Loaded into my son’s 3 series with a fork lift, I had to take it to bits to get it back out. Auto, reckoned to have done 70 something, untested and unwarranted. From the plastics the mileage looks about right. Not spectacular compression turning it over, but I’ll be stripping it, plastigauge the bottom end, balance everything with the lightweight flywheel, and fiddle with the head.

Pity I no longer have a flow bench, and definitely no space to build a new one, it’ll be port forms and guesswork.

Picked up a spare engine today though. Loaded into my son’s 3 series with a fork lift, I had to take it to bits to get it back out. Auto, reckoned to have done 70 something, untested and unwarranted. From the plastics the mileage looks about right. Not spectacular compression turning it over, but I’ll be stripping it, plastigauge the bottom end, balance everything with the lightweight flywheel, and fiddle with the head.

Pity I no longer have a flow bench, and definitely no space to build a new one, it’ll be port forms and guesswork.

- Joined

- Jul 18, 2020

- Points

- 128

- Location

- Portchester, Fareham

- Model of Z

- 1998 BMW Z3 Individual 1.9 M44 B19

Hope you get better soon mateGotten next to nothing done, a cold turned into a chest infection, that turned into pneumonia and chest pains. So a visit to hospital, beta blockers and blood thinners mean I’m continually cold which will be lovely heading into a Scottish winter. At least until I get a precautionary angiogram. Lovely.

Picked up a spare engine today though. Loaded into my son’s 3 series with a fork lift, I had to take it to bits to get it back out. Auto, reckoned to have done 70 something, untested and unwarranted. From the plastics the mileage looks about right. Not spectacular compression turning it over, but I’ll be stripping it, plastigauge the bottom end, balance everything with the lightweight flywheel, and fiddle with the head.

View attachment 281069

View attachment 281071

Pity I no longer have a flow bench, and definitely no space to build a new one, it’ll be port forms and guesswork.

I would say I’m fine, but I’m typing this from a hospital bed after chest pains, in until tomorrow

.

.

I was fed up borrowing cars and bought an SLK because I couldn’t find another Z worth buying locally.

Only 44k, it’ll do.

I was curious why a compact with only 70K would be turned into a drift car. Stripped the head off the engine. Decent condition.

The condition of the plastics tally with the mileage of ~70K, IMO anyway.

But I took off the thermostat to find this

Obviously that missing piece, which will be in the block somewhere, means the engine would never get to temperature.

Things went a bit tits up at that point, as I went to hoist the block to mount it on the engine stand, it fell over. Yes, oil EVERYWHERE! Cue mad dash to pick it up again, oily footprints all over the place.

Third layer of cat litter and the shed floor was like this.

Still needs mopped To get all the cat litter remnants, but it’s not as bad as I feared.

These arrived from the States just before I went to visit the Doc, roll cage tools.

Roll hoop for the Z and rear cage for my lads Mini.

I was fed up borrowing cars and bought an SLK because I couldn’t find another Z worth buying locally.

Only 44k, it’ll do.

I was curious why a compact with only 70K would be turned into a drift car. Stripped the head off the engine. Decent condition.

The condition of the plastics tally with the mileage of ~70K, IMO anyway.

But I took off the thermostat to find this

Obviously that missing piece, which will be in the block somewhere, means the engine would never get to temperature.

Things went a bit tits up at that point, as I went to hoist the block to mount it on the engine stand, it fell over. Yes, oil EVERYWHERE! Cue mad dash to pick it up again, oily footprints all over the place.

Third layer of cat litter and the shed floor was like this.

Still needs mopped To get all the cat litter remnants, but it’s not as bad as I feared.

These arrived from the States just before I went to visit the Doc, roll cage tools.

Roll hoop for the Z and rear cage for my lads Mini.

Last edited:

Great write up Iain with good photos, Intrigued to see how the car pans out and hope your health is improving.

I’m new to the forum and going to look at a Z3 local to me tomorrow, just out of curiosity where up north of Perth are you, I’m in Fife and would be interested in hearing from some of the Scotish gang.

I’m new to the forum and going to look at a Z3 local to me tomorrow, just out of curiosity where up north of Perth are you, I’m in Fife and would be interested in hearing from some of the Scotish gang.

I’m in Luncarty, the first village North of Perth on the A9. Do watch your speed if you’re passing this way, there’s a new bridge being built and the camera vans are out constantly.

Progress going to become even slower I’m afraid, been diagnosed with unstable angina, banned from driving for 4 weeks until all the meds are sorted. No exertion, no straining, no lifting. . . Like that’s going to happen. Though my wife has said if I say, “I’m Fine”, one more time to her whilst using nitro spray, she’ll slap me so hard I won’t be fine. Since I’ve discovered it gives me a colossal headache, that wouldn’t be difficult.

Which model are you looking at?

Progress going to become even slower I’m afraid, been diagnosed with unstable angina, banned from driving for 4 weeks until all the meds are sorted. No exertion, no straining, no lifting. . . Like that’s going to happen. Though my wife has said if I say, “I’m Fine”, one more time to her whilst using nitro spray, she’ll slap me so hard I won’t be fine. Since I’ve discovered it gives me a colossal headache, that wouldn’t be difficult.

Which model are you looking at?

My sister and her husband have just left mine after a visit, they stay in Birman so not far from you, we are up the A9 regular as my son stays in Forres,

I was looking at a 2001 1.8/9 with 67000 miles , had a drive in it today and it seemed to perform not bad.

it had a 1.8 badge on the rear but said 1.9 on the log book, in your opinion is this a good choice or should I look for a six cylinder, the car seems in reasonable condition with the odd scuff here and there , it does have service history as well.

It’s a private sale at £1500. The engine was quiet as was the diff and it had recent shocks and springs on the rear, mot it August next year.

I'm not sure if this is the lower powered engine and the one to avoid or not.

any advice appreciated.

Cheers Brian

I was looking at a 2001 1.8/9 with 67000 miles , had a drive in it today and it seemed to perform not bad.

it had a 1.8 badge on the rear but said 1.9 on the log book, in your opinion is this a good choice or should I look for a six cylinder, the car seems in reasonable condition with the odd scuff here and there , it does have service history as well.

It’s a private sale at £1500. The engine was quiet as was the diff and it had recent shocks and springs on the rear, mot it August next year.

I'm not sure if this is the lower powered engine and the one to avoid or not.

any advice appreciated.

Cheers Brian

From the year and description looks like the single cam, the one to avoid!!

I don't know about 1.8 but there's there's two 1.9's. Mine is the twin Over Head Cam 16v (4 Cylinder)

You can see the twin cam cover with the plastic, kind of recessed, BMW strip down the middle between the cams

The single cam lower powered one is like this

You can see the twin cam cover with the plastic, kind of recessed, BMW strip down the middle between the cams

The single cam lower powered one is like this

This is the information I’m looking for, as I’m new to Z3’s, can you give me any info why?From the year and description looks like the single cam, the one to avoid!!

When I bought my 1.9 4cyl nigh on 20 years ago I didn't know anything about 6 cyl versions of it. I just saw the car and loved it and, for me, 140 HP is enough anyway.

But, now that I know a bit more about zed's if I was buying again I'd go for a 3.0 Not because of the extra power but because it's those bigger engined ones that hold their value.

But, now that I know a bit more about zed's if I was buying again I'd go for a 3.0 Not because of the extra power but because it's those bigger engined ones that hold their value.