M52 manifold swap

- Thread starter Slam

- Start date

Just been looking on the website of the company that carried out my conversion and they now seem to fit a modified m50 manifold to the m52 engine. Checking my invoice it also had the software upgrade.

You will have a M50B25 inlet manifold on your non TU M52B28. Its a different set up to what is being discussed in this tread and does not have a DISA Valve.I have a M52B28 (not TU) engine with a 2.5 manifold. Looking at throttle bodies and DISA valves for power gains. Bit confused as to if I should get a throttle body from a bigger engine or have it rebored? Also would a bigger DISA fit on the 2.5 manifold?

Sorry, I can't help you with your throttle body question

Isn't this for the non TU engine? As the M50 manifold conversion is for the early 2.8 (non TU), if yours has the later engine (TU) then it won't have had that upgrade? Not sure why it says TU in the title, I can't see how the M50 fits the TU engine it needs an M54 manifold. They must have modified your standard manifold in some form, be interesting to see what once it's off.View attachment 85913 Forgot to upload it !

No mine is the later TU manifold not the m50.Isn't this for the non TU engine? As the M50 manifold conversion is for the early 2.8 (non TU), if yours has the later engine (TU) then it won't have had that upgrade? Not sure why it says TU in the title, I can't see how the M50 fits the TU engine it needs an M54 manifold. They must have modified your standard manifold in some form, be interesting to see what once it's off.

Thought so, on that web page they advertise the M50 conversion for both engines and it doesn't fit the TU. They couldn't have done the upgrade listed on that screenshot to yours.

- Joined

- Apr 27, 2012

- Points

- 100

Somewhat belated entry into this discussion... I have a fully cleaned up M54B30 IM sitting on my coffee table complete with DISA and adapter plate... From the previous posts here it seems that the only fundamental difference in modification for £1000 was the throttle body was bored out and a larger butterfly fitted. Although the IM was also "machined" - by which I assume the runners were machined at the cylinder head ends to assume the same "D" shape.

Having just recently spent 3 days cleaning up the M54 IM, the "D" shape on the M54 manifold ends aproximately 65mm into the runners and thereafter they are oval heading back to the throttle body side of the IM.

What does this mean with regards to improved airflow / intake other than that the flow into the cylinder head ports is matched.

I have read conflicting comments about the length of the M54 runners being shorter than the M52TU runners and some comments that they are longer... Until I take my TU IM off I can't verify what is true or if there is any difference in length at all.

But if anyone also has an M54 IM uninstalled, you can put a finger inside the runner at the square corner of the "D" and follow it inwards. You will find it tapers off just as the bend begins and thereafter the runner walls become oval.

Notwithstanding, it must be an improvement otherwise BMW would not have bothered.. But is this "D" only a requirement for the 3.0 plus size motors since they require more air ??

I have only seen one set of comparative dyno logs of before and after the swap. This showed a 13 HP gain at the crank. I'm not sure what that means HP at the crank or the wheels is Greek to me - what's the difference??

Is 13HP at the crank 5 or 20 HP at the wheels??

Anyhow, I had planned an early start tomorrow to strip out the OEM IM and fit the M54b30 IM... now I'm not sure if it's worth the effort or not.

I do know that @Antm72 mentioned to me of "someone" on the forum who had done this mod, but that he had had the OEM TB Bored larger.

I assume that would be @Portmyster who makes reference to it above.

@Antm72 also tells me there's a fella on eBay that offers the "larger bore" M52TU throttle body - I did an eBay search but found nothing in that regard...

Having looked at my OEM throttle body, it doesn't really look like one can bore it out more than 2mm in total diameter increase. That would mean very little gain, or perhaps not ??

I would be interested to hear from any and all what their experiences are or if they can add any verifiable information about this modification.

Having just recently spent 3 days cleaning up the M54 IM, the "D" shape on the M54 manifold ends aproximately 65mm into the runners and thereafter they are oval heading back to the throttle body side of the IM.

What does this mean with regards to improved airflow / intake other than that the flow into the cylinder head ports is matched.

I have read conflicting comments about the length of the M54 runners being shorter than the M52TU runners and some comments that they are longer... Until I take my TU IM off I can't verify what is true or if there is any difference in length at all.

But if anyone also has an M54 IM uninstalled, you can put a finger inside the runner at the square corner of the "D" and follow it inwards. You will find it tapers off just as the bend begins and thereafter the runner walls become oval.

Notwithstanding, it must be an improvement otherwise BMW would not have bothered.. But is this "D" only a requirement for the 3.0 plus size motors since they require more air ??

I have only seen one set of comparative dyno logs of before and after the swap. This showed a 13 HP gain at the crank. I'm not sure what that means HP at the crank or the wheels is Greek to me - what's the difference??

Is 13HP at the crank 5 or 20 HP at the wheels??

Anyhow, I had planned an early start tomorrow to strip out the OEM IM and fit the M54b30 IM... now I'm not sure if it's worth the effort or not.

I do know that @Antm72 mentioned to me of "someone" on the forum who had done this mod, but that he had had the OEM TB Bored larger.

I assume that would be @Portmyster who makes reference to it above.

@Antm72 also tells me there's a fella on eBay that offers the "larger bore" M52TU throttle body - I did an eBay search but found nothing in that regard...

Having looked at my OEM throttle body, it doesn't really look like one can bore it out more than 2mm in total diameter increase. That would mean very little gain, or perhaps not ??

I would be interested to hear from any and all what their experiences are or if they can add any verifiable information about this modification.

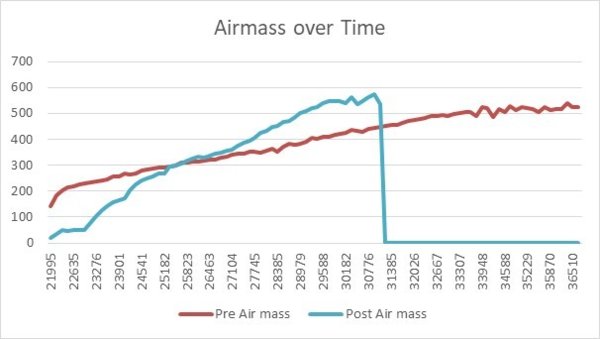

I have done a very similar modification twice. Fitting a M54B25 IM on to M52TUB engines. Both where tested before and after via a WOT run using "TestO" a data logging app that runs on the same communication bus as INPA. TestO link below

http://www.bimmerforums.com/forum/showthread.php?1830510-Diagnostic-program-with-realtime-graph-view

Fitting the M54B25 IM to a 2000 323i with M52TUB25 engine provided good gains. See chart attached. Used Air Mass Flow as a proxy for HP. The new IM had "D" shaped runners and 10 mm shorter runners.

Fitting the M54B25 IM to a 2000 Z3 with M52TUB20 engine provided no gains. The IM was not a limitation is the system for that engine.

While the test method is not Dyno runs and the IM used is smaller than the M54B30 that you are using, My test results indicate that you will get some good gains.

Edit: The same IM is used as standard on all M52TUB engines.

http://www.bimmerforums.com/forum/showthread.php?1830510-Diagnostic-program-with-realtime-graph-view

Fitting the M54B25 IM to a 2000 323i with M52TUB25 engine provided good gains. See chart attached. Used Air Mass Flow as a proxy for HP. The new IM had "D" shaped runners and 10 mm shorter runners.

Fitting the M54B25 IM to a 2000 Z3 with M52TUB20 engine provided no gains. The IM was not a limitation is the system for that engine.

While the test method is not Dyno runs and the IM used is smaller than the M54B30 that you are using, My test results indicate that you will get some good gains.

Edit: The same IM is used as standard on all M52TUB engines.

Attachments

-

37 KB Views: 80

Last edited:

- Joined

- Apr 27, 2012

- Points

- 100

I think I may just stick to OEM and flog my M54B30 as a complete ready to install upgrade to someone else.

BTW.... I have "redesigned" the adapter plate so that instead of being 10mm thick it's just 4mm thick. This will prevent the issues caused by the extra 6mm where the rubber boot is pushed up against the strut tower and electrical distribution box adjacent to the TB is displaced far less.

One last point I would like to address is the position of the M52TU TB relative to the round hole in the M54 IM.

Using the Bimmertune adapter, the TB is not central to the IM hole. Since I'm not an egghead familiar with flow dynamics, I can't say this if is a problem or not in terms of the air movement inside the M54 IM once it has passed through the "off center M52TU TB. It would seem that the TB should be centralised to the IM hole - anyone have more knowledge about airflow ??

Ideally I would really like to get a M52TU TB which I can take apart. A dead one will do, since what I would look at is the way the electronics side fits to the aluminium side.

It may be a proposition to have a new aluminium part machined with the same design as the OEM where it interfaces with the electronics component, but have a fully large aluminium throttle and butterfly and correct mounting positions to suit the M54 IM.

That would then ensure the airflow is correct relative to the design of the M54 IM.

The most "common sense" approach would be to remove the OEM IM and have the runners machined to the "D" shape of the cylinder head. I don't think the larger DISA makes a substantial difference to performance and it only takes effect above 3500 - 4000rpm anyhow.

The M54 DISA needs to be larger to handle the airflow through the M54 TB which is itself considerably larger than the M52TU TB... The M52TU TB will only allow the same volume of air to pass through as it does with an OEM IM. So the only "restriction" is at the IM / Head interface due to the IM runners being oval. Machining the runners will eliminate that anomaly and provide the best all round result.

BTW.... I have "redesigned" the adapter plate so that instead of being 10mm thick it's just 4mm thick. This will prevent the issues caused by the extra 6mm where the rubber boot is pushed up against the strut tower and electrical distribution box adjacent to the TB is displaced far less.

One last point I would like to address is the position of the M52TU TB relative to the round hole in the M54 IM.

Using the Bimmertune adapter, the TB is not central to the IM hole. Since I'm not an egghead familiar with flow dynamics, I can't say this if is a problem or not in terms of the air movement inside the M54 IM once it has passed through the "off center M52TU TB. It would seem that the TB should be centralised to the IM hole - anyone have more knowledge about airflow ??

Ideally I would really like to get a M52TU TB which I can take apart. A dead one will do, since what I would look at is the way the electronics side fits to the aluminium side.

It may be a proposition to have a new aluminium part machined with the same design as the OEM where it interfaces with the electronics component, but have a fully large aluminium throttle and butterfly and correct mounting positions to suit the M54 IM.

That would then ensure the airflow is correct relative to the design of the M54 IM.

The most "common sense" approach would be to remove the OEM IM and have the runners machined to the "D" shape of the cylinder head. I don't think the larger DISA makes a substantial difference to performance and it only takes effect above 3500 - 4000rpm anyhow.

The M54 DISA needs to be larger to handle the airflow through the M54 TB which is itself considerably larger than the M52TU TB... The M52TU TB will only allow the same volume of air to pass through as it does with an OEM IM. So the only "restriction" is at the IM / Head interface due to the IM runners being oval. Machining the runners will eliminate that anomaly and provide the best all round result.

Last edited:

- Joined

- Apr 27, 2012

- Points

- 100

.... afterthought - the real restriction has to be the M52TU TB. 200cc between the 2.8 and 3.0 is minimal - the real difference is the huge TB fitted to the 3.0 together with it's larger fuel delivery injectors and different mapping to suit those increased capacities.

If the M52TU cylinder head ports had been oval and the runners "D" shaped that would have caused a serious restriction - the fact that the runners are oval and the head is "D" shaped is a minimal if any issue - it's the TB which needs to be larger- lots larger, to achieve significant power gains.

If the M52TU cylinder head ports had been oval and the runners "D" shaped that would have caused a serious restriction - the fact that the runners are oval and the head is "D" shaped is a minimal if any issue - it's the TB which needs to be larger- lots larger, to achieve significant power gains.

- Joined

- Apr 27, 2012

- Points

- 100

Does anyone here have an OEM M52TU IM lying about ?

If so, I need some measurements please.

If you also have a vernier that will help for accuracy. I need the shortest measurement from the edge of the 4 holes to the main big hole in the IM.

I want to determine the exact position of the TB hole in relation to the the large IM hole. Basically it requires a 45 degree line from the TB mounting holes on the IM to the edge of the IM hole. Don't worry about trying to measure to the center of the mounting hole - that is a simple addition of 3mm since the bolts are M6 which hold the TB to the IM.

Grateful for any assistance.

If so, I need some measurements please.

If you also have a vernier that will help for accuracy. I need the shortest measurement from the edge of the 4 holes to the main big hole in the IM.

I want to determine the exact position of the TB hole in relation to the the large IM hole. Basically it requires a 45 degree line from the TB mounting holes on the IM to the edge of the IM hole. Don't worry about trying to measure to the center of the mounting hole - that is a simple addition of 3mm since the bolts are M6 which hold the TB to the IM.

Grateful for any assistance.

.

Last edited:

- Joined

- Apr 27, 2012

- Points

- 100

I didn't deny the benefit of the mod. But considering the modest gain it achieves, I don't think it is the best route to go without considering the possibilities of a better way to effect the mod so that the result is a 2.8 that will perform as well as a 3.0.

My comments were not made to belittle the mod as it is currently performed or those people who have chosen to make the mod. My comments were made to provide some food for thought and possibly inspiration to do better than the basic swap as it exists currently.

As I said above, I have already designed a better adapter format which will reduce the current 10mm thick adapter to just 4mm. Also, I raised 2 connected points, 1. The limitations of the small M52 TB bore, and 2. the possibility of having a large TB machined to attach to the electronics section of the OEM M52TU TB.

I don't believe it would be prohibitive in cost and could be done easily on a 5 axis CNC machine. Hence my comment about acquiring a "dead" M52TU TB which could be stripped and used as the sample to ensure correct and applicable connection to a new large TB which could bolt directly to the M54 IM. The aluminium section of the OEM only serves to house the butterfly and act as a conduit for the inflow of air.

Once that is accomplished, the direct swap of the M54 cams into the M52 TU can be done as well as injectors capable of delivering sufficient fuel and lastly a re-map to get the best out of the changes. The M54 cams need no modification to fit, and are relatively cheap, and although they are not as effective as Schricks, they will add a heap more grunt. And, since the cams are being done, it would be opportune to completely remove the head and give it a thorough overhaul and look into larger inlet and exhaust valves. It's likely that it would be less hassle or expense simply to buy a 3.0, but it wouldn't be as much fun as taking the 52TU and whipping the 54's butt.

Once again, I apologize if it appeared I was "poo poeing" or belittling anyone.

So, anyone who may have a dead TU TB.... I'll pay the shipping and development of a true large bore TB which can be driven by the MS42 DME...

My comments were not made to belittle the mod as it is currently performed or those people who have chosen to make the mod. My comments were made to provide some food for thought and possibly inspiration to do better than the basic swap as it exists currently.

As I said above, I have already designed a better adapter format which will reduce the current 10mm thick adapter to just 4mm. Also, I raised 2 connected points, 1. The limitations of the small M52 TB bore, and 2. the possibility of having a large TB machined to attach to the electronics section of the OEM M52TU TB.

I don't believe it would be prohibitive in cost and could be done easily on a 5 axis CNC machine. Hence my comment about acquiring a "dead" M52TU TB which could be stripped and used as the sample to ensure correct and applicable connection to a new large TB which could bolt directly to the M54 IM. The aluminium section of the OEM only serves to house the butterfly and act as a conduit for the inflow of air.

Once that is accomplished, the direct swap of the M54 cams into the M52 TU can be done as well as injectors capable of delivering sufficient fuel and lastly a re-map to get the best out of the changes. The M54 cams need no modification to fit, and are relatively cheap, and although they are not as effective as Schricks, they will add a heap more grunt. And, since the cams are being done, it would be opportune to completely remove the head and give it a thorough overhaul and look into larger inlet and exhaust valves. It's likely that it would be less hassle or expense simply to buy a 3.0, but it wouldn't be as much fun as taking the 52TU and whipping the 54's butt.

Once again, I apologize if it appeared I was "poo poeing" or belittling anyone.

So, anyone who may have a dead TU TB.... I'll pay the shipping and development of a true large bore TB which can be driven by the MS42 DME...

- Joined

- Aug 4, 2016

- Points

- 77

- Model of Z

- 2.8 Individual Fiji Green

Apologies for being late to the table. I did the M54B30 TU conversion and as you pointed out the elbow did push up against the strut tower etc.

I did use a Dremel to remove the lip from the manifold that was created by the TB adapter - just seemed a sensible thing to do.

I was in conversation with the guy on eBay who does the bigger TBs for the M52 and he said "I've modified a TU throttle body once and never again!" stating that it was a !!! too do; I don't know why but that's what he said.

Hope that helps?

I did use a Dremel to remove the lip from the manifold that was created by the TB adapter - just seemed a sensible thing to do.

I was in conversation with the guy on eBay who does the bigger TBs for the M52 and he said "I've modified a TU throttle body once and never again!" stating that it was a !!! too do; I don't know why but that's what he said.

Hope that helps?

- Joined

- Apr 27, 2012

- Points

- 100

I have found a M52TU TB locally which I plan to dismantle - carefully.Apologies for being late to the table. I did the M54B30 TU conversion and as you pointed out the elbow did push up against the strut tower etc.

I did use a Dremel to remove the lip from the manifold that was created by the TB adapter - just seemed a sensible thing to do.

I was in conversation with the guy on eBay who does the bigger TBs for the M52 and he said "I've modified a TU throttle body once and never again!" stating that it was a !!! too do; I don't know why but that's what he said.

Hope that helps?

Next year I'll be taking it to my buddy with the 5 axis CNC machine.

My instructions - Copy identically the fitting pattern on the electronics side and the throttle cable side. Between those aspects, machine a 80mm throttle with mounting positions to fit the M54 Intake manifold, and machine an appropriately long shaft to allow transition from the electronics side, through the larger TB, to the mechanism for the cable.

Once he's done one, the "pattern" is in the machine's memory and it'll be a question of put the material in place and push the "Start" button.

I've looked at the idea of boring out the OEM TB, but it's basically a waste of time to gain 2 - 3mm and still leave the butterfly standard size which means it will have the same bore albeit over a shorter length inside the TB.

C

cameron.white

Guest

t's literally plug and play except for having the ECU flashed. If you don't already have every OBD1 sensor sitting around it's cheaper too.

- Joined

- Oct 26, 2014

- Points

- 181

- Model of Z

- Z4 coupe sport.

Hi Southernboy, I tried for some time in 2017 to get a big bore TB for my 2.8tu and was told after many inquiries that no one does it or that it can’t be done. No reasons were given and even Riot Racing in USA told me the same so I gave up. If someone actually does manufacture one then I believe that the numbers actually wanting this mod would not be anywhere near enough to sustain a production run with costs unable to be covered or the mod being too expensive for players to even consider. Having said this I believe it’s not beyond the scope of a good mech/elect engineer, once the bore is opened up between 5-7mm they will then have to match the various computer programs to enable it to work and then only get a probable 5-7bhp. All this taken into consideration will no doubt put most engineers off doing this mod more than a couple of times. RR USA haven’t bothered so good luck to you and your engineer friend, I’ll follow your journey with great interest.

RHA,Roy.

RHA,Roy.

- Joined

- Apr 27, 2012

- Points

- 100

You're right about the potential costs. However, as per my post, I'm planning on a complete new part - the aluminium part.

The operation of the mechanism will still be driven by the same electronics part of the TB, so no new programming will be required. All that changes in effect is the size of the aluminium side of the TB and that it will be able to bolt directly to the M54 manifold.

This together with my intention to replace the intake camshaft with one from the M54 3.0. it will bring the intake system up to par with the 3.0 intake system. The only difference will then be the overall 200cc smaller engine capacity - which equates to just 33.33333 cc per cylinder less than the 3.0 motor. I imagine the final improvement in HP will be as near as dammit to the 3.0 HP output.

There is only one final difference other than the 200cc - that is, the 3.0 has pistons with shorter sleeves which obviously reduces friction inside the cylinder, but changing pistons requires a complete engine strip down which really isn't worth the effort for 2 or 3 HP. I expect an overall gain should be in the region of 25 - 30 HP to around 220 'ish from the official spec of 193 HP for the TU 2.8. At 220 HP, it would be just 5 HP shy of the 3.0 OEM spec of 225 HP. Perhaps with a re-map / chip tune etc, it may make as much or even more. Certainly in the acceleration stakes it should out perform the 3.0 given that the 2.8 TU has a shorter stroke than the 3.0 and will rev up a little quicker. Once all the above is in place, I will look at the option of larger injectors to compensate the greater air intake, but the OEM injectors could be adequate given that a re-map / tune could be done so that the OEM injectors are opened fractionally longer than currently in the OEM DME programme.

The operation of the mechanism will still be driven by the same electronics part of the TB, so no new programming will be required. All that changes in effect is the size of the aluminium side of the TB and that it will be able to bolt directly to the M54 manifold.

This together with my intention to replace the intake camshaft with one from the M54 3.0. it will bring the intake system up to par with the 3.0 intake system. The only difference will then be the overall 200cc smaller engine capacity - which equates to just 33.33333 cc per cylinder less than the 3.0 motor. I imagine the final improvement in HP will be as near as dammit to the 3.0 HP output.

There is only one final difference other than the 200cc - that is, the 3.0 has pistons with shorter sleeves which obviously reduces friction inside the cylinder, but changing pistons requires a complete engine strip down which really isn't worth the effort for 2 or 3 HP. I expect an overall gain should be in the region of 25 - 30 HP to around 220 'ish from the official spec of 193 HP for the TU 2.8. At 220 HP, it would be just 5 HP shy of the 3.0 OEM spec of 225 HP. Perhaps with a re-map / chip tune etc, it may make as much or even more. Certainly in the acceleration stakes it should out perform the 3.0 given that the 2.8 TU has a shorter stroke than the 3.0 and will rev up a little quicker. Once all the above is in place, I will look at the option of larger injectors to compensate the greater air intake, but the OEM injectors could be adequate given that a re-map / tune could be done so that the OEM injectors are opened fractionally longer than currently in the OEM DME programme.