I was wondering about that, on my car the collapse is now “permanent” and I’m wondering if I should be fixing the vacumn issue, and how to do that. Something to do with the charcoal cannister? And a valve?The rubbing on the back is due to collapse of the tank due to vacuum when running the tank to empty (as the vac release mechanism on all our cars fails).

Fuel sender unit, ceramic resistor availability?

- Thread starter Kiwipom

- Start date

I very much doubt it’s permanent. It’s a function of vacuum and outside temp. People have reported that there is an anti vac valve that has failed. I did not go that avenue (did not find accurate info)

It’s a long story - have a look at my exhaustive thread on the subject. Easiest way now is to release the cap every 100 miles. A vented cap suitable for our car is no longer available (was for a classic mini - but new design leaks with a full tank).

It’s a long story - have a look at my exhaustive thread on the subject. Easiest way now is to release the cap every 100 miles. A vented cap suitable for our car is no longer available (was for a classic mini - but new design leaks with a full tank).

Last edited:

By permanent I meant if I fit a unmodified pump assembly the sender section will foul the rear wall of the tank, so it appears to have distorted and stayed distorted.I very much doubt it’s permanent. It’s a function of vacuum and outside temp. People have reported that there is an anti vac valve that has failed. I did not go that avenue (did not find accurate info)

It’s a long story - have a look at my exhaustive thread on the subject. Easiest way now is to release the cap every 100 miles. A vented cap suitable for our car is no longer available (was for a classic mini - but new design leaks with a full tank).

Due to my “other” hobby I know fuel tank vent systems are commonly deleted on motorbikes, and if necessary a “dongle” fitted to prevent any ECU issues that arise from that. A dongle might simply be a connector of the right type with a resistor of the right value in it, to replace the removed vent system component, if it was wired into the harness. The vent then might simply be a small hose run from the tank to a high part of the bike, and yes fumes will come out of that hose.

Is some mod like that required to vent the z3 tank? and prevent a (damaging) vacuum occurrring?

There are 2 hoses connected to the pump assembly, one is the fuel supply to the engine, the other I don”t know but the pump assembly has a one way valve inside for it, I didn’t investigate it thinking it was probably a fuel return hose, but, is that second hose the only vent hose for the tank?

How are you sure that an unmodified pump scratches the back of the tank? I assume that the tank retreats to its original position because once the vac is released it can be filled with the full 50+ litres of fuel.

During test fitting both the oem pump and aftermarket both fouled the tank, and failed the “pull up with string” test, so 99% sure,How are you sure that an unmodified pump scratches the back of the tank? I assume that the tank retreats to its original position because once the vac is released it can be filled with the full 50+ litres of fuel.

I also went to great lengths to measure the protrusion of the sender unit and space for it in the tank, I made a approx 4”x3” cylinder of cardboard that replicated the size of the pump assembly and put cling film over one end and trial fitted that in the rubber gasket mounted in the tank and it was clear the tank impinged on where the swivelling part of the sender needs to go. The clearance I created is still only a few mm so I doubt the fuel capacity would change much due to the wall moving enough to jam the sender.

Before doing the above I established no amount of bending the float wire resulted in the passing the “string” test, and due to lots of trial and error

There are several issues that result in the sender not working, impacting the tank (regardless of a vacuum) is just one of them. I am still pretty determined to remove any possibility of a vacuum occurring by some mod to create a simple vent. I am pretty fed up with draining the tank and fitting and refitting the pump assembly

The e36 forums have some info on mods to race cars where the oem vent system is not working for one reason or another, and according to the z3 parts diagrams the “other” hose to the pump assembly IS a fuel return, and there is a third hose (I think) that goes to the charcoal cannister. I’m still researching all that though.

Last edited:

Can you clarify exactly which pic is the optimal shape of the float wire that clears the wall? I see 2 pics and they look different.During test fitting both the oem pump and aftermarket both fouled the tank, and failed the “pull up with string” test, so 99% sure,

I also went to great lengths to measure the protrusion of the sender unit and space for it in the tank, I made a approx 4”x3” cylinder of cardboard that replicated the size of the pump assembly and put cling film over one end and trial fitted that in the rubber gasket mounted in the tank and it was clear the tank impinged on where the swivelling part of the sender needs to go. The clearance I created is still only a few mm so I doubt the fuel capacity would change much due to the wall moving enough to jam the sender.

Before doing the above I established no amount of bending the float wire resulted in the passing the “string” test, and due to lots of trial and errorI have now found the best way of bending that wire (see pics), so the wire clears the quite narrow gap between front and rear walls, and that the float does not get stuck on the ledge on the rear wall when the tank is full.

There are several issues that result in the sender not working, impacting the tank (regardless of a vacuum) is just one of them. I am still pretty determined to remove any possibility of a vacuum occurring by some mod to create a simple vent. I am pretty fed up with draining the tank and fitting and refitting the pump assemblyI don’t want to have buy another pump and fit it.

The e36 forums have some info on mods to race cars where the oem vent system is not working for one reason or another, and according to the z3 parts diagrams the “other” hose to the pump assembly IS a fuel return, and there is a third hose (I think) that goes to the charcoal cannister. I’m still researching all that though.

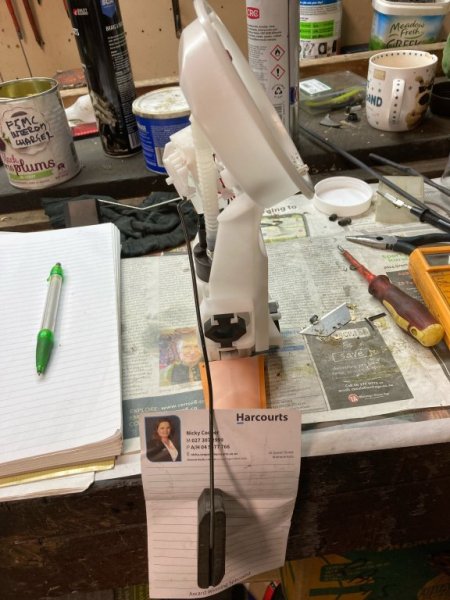

These 2 pics show the end result of bending, it’s difficult to take a pic that clearly shows the bend, the first adjustment needs to be made to the “twist” in the wire right next to the sensor, to make sure the wire does not contact the rear tank wall (noting my other comment about “feeding” the wire through the clip in the sender rather than clipping it).

Attachments

-

167 KB Views: 49

-

99.4 KB Views: 47

Last edited:

Been googling…this from bimmer forum…….I know not to believe everything on the net buts it’s something to watch out for when deleting the evap system….I have the same 2.8. I think the conclusion is that you get a CEL if you remove the evap solenoid (as part of deleting the cannister etc and venting the tank to atmosphere to prevent a vacuum build up), and you get a loss of power if you get rid of the CEL using a resistor to emulate the solenoid.

”I have a 2.8 Z3, with the newer M52TUB28 engine. When I bought it, the EVAP solenoid was physically broken off the line that goes to the intake, so I blanked the hose and lived with it so far. The only thing is, if the solenoid is plugged in the car will intermittently stop pulling for a moment, so I'd imagine fooling the computer with a resistor will cause the same.

As for the reasoning, it's actually simple. When the computer tells the solenoid to open, it expects petrol vapours to be pulled into the manifold. So to compensate, it cuts back on fuel injected (to keep the mixture right). No vapours means the engine leans out, and that's what causes the loss of power. With the solenoid disconnected that issue is gone, but obviously there's a fault code. So unless it's possible to code the solenoid out, I don't think it's possible to have your cake and eat it.”

”I have a 2.8 Z3, with the newer M52TUB28 engine. When I bought it, the EVAP solenoid was physically broken off the line that goes to the intake, so I blanked the hose and lived with it so far. The only thing is, if the solenoid is plugged in the car will intermittently stop pulling for a moment, so I'd imagine fooling the computer with a resistor will cause the same.

As for the reasoning, it's actually simple. When the computer tells the solenoid to open, it expects petrol vapours to be pulled into the manifold. So to compensate, it cuts back on fuel injected (to keep the mixture right). No vapours means the engine leans out, and that's what causes the loss of power. With the solenoid disconnected that issue is gone, but obviously there's a fault code. So unless it's possible to code the solenoid out, I don't think it's possible to have your cake and eat it.”