A BMW Z3 SHORT SHIFT GEARLEVER – and other BMWs

How to create a Z3 short shift

Most manufacturers fit gear levers which are designed to reduce the effort required to that deemed acceptable for the more weak-wristed amongst us. This usually produces a long lever, with a gear change of excessive travel, which in a small car such as a Z3 is not the ergonomic ideal.

A number of after-market short shifters are available, but do not be impressed by claims that they are manufactured from stainless steel (‘Aircraft quality,’ naturally!) bear the ‘magic’ of an AC Schnitzer logo (meaning over-priced!) or have a ‘lift up’ collar to protect against engagement of reverse (the gearbox still has its protective spring loading).

Some manufacturers claim that the use of sealed ball races to replace the plastic bush at the base of the gear lever will improve gear change quality. If given a little grease the original bearing does not produce any appreciable resistance, and its width provides better resistance to lateral free play when slightly worn than can be provided by any ball race.

Regardless of such claimed sophistication, the basic principles are very simple, effort, leverage and travel always being associated quantities. Remember the saying that ‘Ye cannot change the laws of physics!’

Reducing gear lever travel can be done in two ways – increasing the distance between the pivot ball and the connection with the gear change rod, or by shortening the upper section of the gear lever, between the pivot ball and the knob. In either case the gear lever action will become heavier, as the amount of leverage exerted by the knob on the gear change rod will be reduced.

Increasing the distance between the pivot ball and gear change rod has the advantage, in some cars, that the original height of the gear lever can be maintained. This is the basis of most after-market short-shift designs, such as those from AC Schnitzer, B&M, and UUC etc.

The finished job – a shortshift lever for 50 pence!

The gear lever of the M Roadster, incidentally, is of this type, combining standard height with a shorter travel than that of the 2.8 litre Z3, which uses the same ZF gearbox. It is said, however, that this lever will not fit the Getrag gearbox used with the smaller engines.

Reducing the height of the gear lever is a very convenient means of reducing gear lever travel if it is felt that the lever is too long. This is the principle behind the Whalen Shift Machine, a knob which sits an inch lower on the gear lever, and which, being made of stainless steel, adds a pound to the mass of the original. The resultant increased inertia adds smoothness to the gear change, in the same manner as a weighted shift rod. At £100 it is probably the best value among proprietary short shifters.

I decided to shorten the lever of my Z3, but preferring to use a hacksaw instead of a credit card, I modified the existing lever. I shortened the lever by one and a half inches, which with a ZF gearbox may make the action a little heavy for the weak-wristed. A one-inch reduction would probably suit most drivers. Further shortening is of course possible, if later considered to be necessary.

[

[

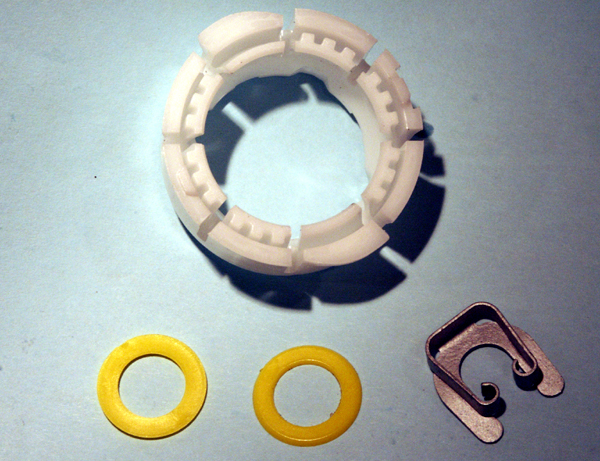

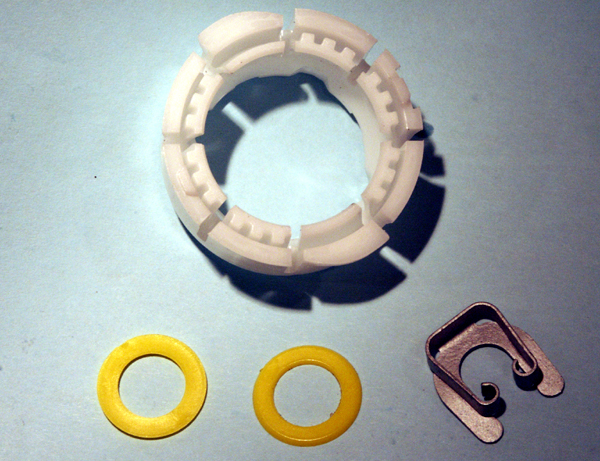

A new clip, thrust washers, and spherical bearing are worth fitting

The work involved is quite straightforward, and within the ability of most owners. Ignore the nonsense contained in the Bentley Z3 repair manual, which insists that to gain access to the gear lever one must first remove the exhaust system, heat shield, and propeller shaft! All work can be done from the driver’s seat.

The gear knob is removed by pressing it sideways and upwards – after a few attempts it will come away from the lever easily, even though Bentley claims that a vertical pull of ninety pounds is necessary! Heather frequently manages to remove the knob while changing gear . . .

The leather lever boot, sound deadening block, and the rubber seal beneath it can then be pulled out, after which the spring clip holding the lever to the shift rod can be seen.

The clip can be pushed off with a large screwdriver, but I bent a pair of needle-nosed pliers to engage into the clip’s ‘ears,’ which makes removal a lot easier.

Bent pliers used to remove clip

Try to prevent the clip from flying away as it is pushed off, and spread a cloth below the pivot to collect it if you fail. Looping a thin wire through the clip will help, but it is wise to have a spare or two, as it will inevitably fall onto the heat shield, never to be seen again.

Remove the yellow plastic thrust washer beneath the clip, then push the pivot pin and the other washer out of the bush at the base of the lever. Again, it is wise to have a few spares.

The lever’s bearing cup is held by small ‘ears’ on its sides – at the 9 and 3 o’clock positions – which engage into the bracket, and can be retracted by careful use two small screwdrivers. To prevent them from returning to their usual positions, slide some old feeler gauges (about 20 thou) or pieces of an old tin can between the ‘ears’ and the housing, after which the lever and pivot can be easily withdrawn. The bearing cup can now be pulled downwards, and removed from the lever.

Gear lever boot etc removed – plastic cup being removed

You will now see that the gear lever takes the form of a solid lower rod, which carries the pivot ball, above which it is surrounded by an upper tubular portion terminating in a rod which carries the gear knob. This tubular portion contains a long rubber bush, on to which the lower rod is bonded.

To ease re-assembly, a mark a line across the upper and lower halves, rembering that you will be removing some of the upper portion – so do not just mark its lower area!

With the gear lever held in a vice by its upper end, heat the mid portion until the rubber insert begins to smoke. Now twist and pull the lower end, continuing to heat and until the two sections separate.

Gear lever sections heated and being seperated after heating

While it is possible to retain the rubber core, sawing through it and replacing the upper portion with adhesive, in my experience it is seldom successful in the long term. A better option is to remove the rubber completely, and fill the space with car body filler. This will remove a lot of unwanted flexibility from the gear change, while maintaining a barrier against heat transfer from the lower section of the lever.

Cut away the rubber tip from the lower section, and then remove all the rubber, and file two flats on the lower portion to provide a good ‘key’ for the body filler. Now cut from each section the amount by which it is desired to shorten the lever, before removing the last traces of rubber and degreasing.

Upper portion of lever being shortened – shorten the lower portion by a similar amount

Using a little silicone rubber, stick the rubber tip previously removed into the end of the upper portion, as this will reduce heat transfer from the tip of the lower portion.

With the upper portion inverted and mounted in a vice, fill it with body filler (I used Isopon) and ensure it is free of air bubbles before aligning the lower portion and slowly inserting it. Wipe away the excess filler (rubber gloves are very handy here) check that both portions of the lever are still in line, and hold them until the filler is cured. Leave in a warm place for a few hours (ideally overnight) to cure completely.

The completed shortshift lever – note the body filler inside the ‘bell’ of the upper portion

Before replacement lightly grease the lever’s lower bush and the bearing cup. After a high mileage, replacement of the cup and plastic thrust washers is advised, as even a small amount of wear will result in a disproportionate amount of sloppiness. A strong wire hook is useful to manipulate the shift rod. Use a new spring clip, and with a small mirror check that its ‘ears’ are snugly located against the five and seven o’clock positions of the pivot pin.

When replacing the rubber seal into the body, remember that it is eccentric – fit it with the hole for the gear lever offset to the right, in order to suit the position of the lever relative to the body aperture.

The result is a gear change which has a shorter travel, but which – particularly in the case of a 2.8, 3 litre, or M Roadster, which are all fitted with the ZF gearbox – is noticeably heavier. For this reason it may be advisable to temper one’s enthusiasm for the hacksaw, although one’s arm muscles will soon compensate.

It did not take long before I no longer noticed the heavier action, but at every gear change I still enjoy the solid and accurate ‘feel’ provided by the rubber-less lever. Selecting reverse is far slicker, as my thumb wraps around the knob, while the fingers pull against the side of the centre console. This is far easier than using arm pressure, or thumping the gear lever to defeat the protective spring loading.

The action is similar to ‘proper’ short-shift gear levers, with the added advantage that it did not cost up to £500. For the price of a tube of body filler, a few cheap spares, and a day’s work, it is excellent value. Even sitting in the car it feels pleasant to move around, and looks good too!

This cheap and simple modification provides a gear change of improved quality, with a precise and short action which is appropriate to the car, and is far more satisfying to use than the original.

How to create a Z3 short shift

Most manufacturers fit gear levers which are designed to reduce the effort required to that deemed acceptable for the more weak-wristed amongst us. This usually produces a long lever, with a gear change of excessive travel, which in a small car such as a Z3 is not the ergonomic ideal.

A number of after-market short shifters are available, but do not be impressed by claims that they are manufactured from stainless steel (‘Aircraft quality,’ naturally!) bear the ‘magic’ of an AC Schnitzer logo (meaning over-priced!) or have a ‘lift up’ collar to protect against engagement of reverse (the gearbox still has its protective spring loading).

Some manufacturers claim that the use of sealed ball races to replace the plastic bush at the base of the gear lever will improve gear change quality. If given a little grease the original bearing does not produce any appreciable resistance, and its width provides better resistance to lateral free play when slightly worn than can be provided by any ball race.

Regardless of such claimed sophistication, the basic principles are very simple, effort, leverage and travel always being associated quantities. Remember the saying that ‘Ye cannot change the laws of physics!’

Reducing gear lever travel can be done in two ways – increasing the distance between the pivot ball and the connection with the gear change rod, or by shortening the upper section of the gear lever, between the pivot ball and the knob. In either case the gear lever action will become heavier, as the amount of leverage exerted by the knob on the gear change rod will be reduced.

Increasing the distance between the pivot ball and gear change rod has the advantage, in some cars, that the original height of the gear lever can be maintained. This is the basis of most after-market short-shift designs, such as those from AC Schnitzer, B&M, and UUC etc.

The finished job – a shortshift lever for 50 pence!

The gear lever of the M Roadster, incidentally, is of this type, combining standard height with a shorter travel than that of the 2.8 litre Z3, which uses the same ZF gearbox. It is said, however, that this lever will not fit the Getrag gearbox used with the smaller engines.

Reducing the height of the gear lever is a very convenient means of reducing gear lever travel if it is felt that the lever is too long. This is the principle behind the Whalen Shift Machine, a knob which sits an inch lower on the gear lever, and which, being made of stainless steel, adds a pound to the mass of the original. The resultant increased inertia adds smoothness to the gear change, in the same manner as a weighted shift rod. At £100 it is probably the best value among proprietary short shifters.

I decided to shorten the lever of my Z3, but preferring to use a hacksaw instead of a credit card, I modified the existing lever. I shortened the lever by one and a half inches, which with a ZF gearbox may make the action a little heavy for the weak-wristed. A one-inch reduction would probably suit most drivers. Further shortening is of course possible, if later considered to be necessary.

A new clip, thrust washers, and spherical bearing are worth fitting

The work involved is quite straightforward, and within the ability of most owners. Ignore the nonsense contained in the Bentley Z3 repair manual, which insists that to gain access to the gear lever one must first remove the exhaust system, heat shield, and propeller shaft! All work can be done from the driver’s seat.

The gear knob is removed by pressing it sideways and upwards – after a few attempts it will come away from the lever easily, even though Bentley claims that a vertical pull of ninety pounds is necessary! Heather frequently manages to remove the knob while changing gear . . .

The leather lever boot, sound deadening block, and the rubber seal beneath it can then be pulled out, after which the spring clip holding the lever to the shift rod can be seen.

The clip can be pushed off with a large screwdriver, but I bent a pair of needle-nosed pliers to engage into the clip’s ‘ears,’ which makes removal a lot easier.

Bent pliers used to remove clip

Try to prevent the clip from flying away as it is pushed off, and spread a cloth below the pivot to collect it if you fail. Looping a thin wire through the clip will help, but it is wise to have a spare or two, as it will inevitably fall onto the heat shield, never to be seen again.

Remove the yellow plastic thrust washer beneath the clip, then push the pivot pin and the other washer out of the bush at the base of the lever. Again, it is wise to have a few spares.

The lever’s bearing cup is held by small ‘ears’ on its sides – at the 9 and 3 o’clock positions – which engage into the bracket, and can be retracted by careful use two small screwdrivers. To prevent them from returning to their usual positions, slide some old feeler gauges (about 20 thou) or pieces of an old tin can between the ‘ears’ and the housing, after which the lever and pivot can be easily withdrawn. The bearing cup can now be pulled downwards, and removed from the lever.

Gear lever boot etc removed – plastic cup being removed

You will now see that the gear lever takes the form of a solid lower rod, which carries the pivot ball, above which it is surrounded by an upper tubular portion terminating in a rod which carries the gear knob. This tubular portion contains a long rubber bush, on to which the lower rod is bonded.

To ease re-assembly, a mark a line across the upper and lower halves, rembering that you will be removing some of the upper portion – so do not just mark its lower area!

With the gear lever held in a vice by its upper end, heat the mid portion until the rubber insert begins to smoke. Now twist and pull the lower end, continuing to heat and until the two sections separate.

Gear lever sections heated and being seperated after heating

While it is possible to retain the rubber core, sawing through it and replacing the upper portion with adhesive, in my experience it is seldom successful in the long term. A better option is to remove the rubber completely, and fill the space with car body filler. This will remove a lot of unwanted flexibility from the gear change, while maintaining a barrier against heat transfer from the lower section of the lever.

Cut away the rubber tip from the lower section, and then remove all the rubber, and file two flats on the lower portion to provide a good ‘key’ for the body filler. Now cut from each section the amount by which it is desired to shorten the lever, before removing the last traces of rubber and degreasing.

Upper portion of lever being shortened – shorten the lower portion by a similar amount

Using a little silicone rubber, stick the rubber tip previously removed into the end of the upper portion, as this will reduce heat transfer from the tip of the lower portion.

With the upper portion inverted and mounted in a vice, fill it with body filler (I used Isopon) and ensure it is free of air bubbles before aligning the lower portion and slowly inserting it. Wipe away the excess filler (rubber gloves are very handy here) check that both portions of the lever are still in line, and hold them until the filler is cured. Leave in a warm place for a few hours (ideally overnight) to cure completely.

The completed shortshift lever – note the body filler inside the ‘bell’ of the upper portion

Before replacement lightly grease the lever’s lower bush and the bearing cup. After a high mileage, replacement of the cup and plastic thrust washers is advised, as even a small amount of wear will result in a disproportionate amount of sloppiness. A strong wire hook is useful to manipulate the shift rod. Use a new spring clip, and with a small mirror check that its ‘ears’ are snugly located against the five and seven o’clock positions of the pivot pin.

When replacing the rubber seal into the body, remember that it is eccentric – fit it with the hole for the gear lever offset to the right, in order to suit the position of the lever relative to the body aperture.

The result is a gear change which has a shorter travel, but which – particularly in the case of a 2.8, 3 litre, or M Roadster, which are all fitted with the ZF gearbox – is noticeably heavier. For this reason it may be advisable to temper one’s enthusiasm for the hacksaw, although one’s arm muscles will soon compensate.

It did not take long before I no longer noticed the heavier action, but at every gear change I still enjoy the solid and accurate ‘feel’ provided by the rubber-less lever. Selecting reverse is far slicker, as my thumb wraps around the knob, while the fingers pull against the side of the centre console. This is far easier than using arm pressure, or thumping the gear lever to defeat the protective spring loading.

The action is similar to ‘proper’ short-shift gear levers, with the added advantage that it did not cost up to £500. For the price of a tube of body filler, a few cheap spares, and a day’s work, it is excellent value. Even sitting in the car it feels pleasant to move around, and looks good too!

This cheap and simple modification provides a gear change of improved quality, with a precise and short action which is appropriate to the car, and is far more satisfying to use than the original.