Ok, most of us fit our own wheels but do we correctly torque up the bolts as they should be?

1. I use a long "stud" to aid with locating the wheel onto the hub. This has a slot cut in the end to facilitate removal if it's a bit tight to turn.

2. Next, I use a short extension and socket to screw in the bolts, again much easier than using just your finger and thumb.

3. Next I use my impact wrench on the lowest setting (1 on my Ryobi tool) to run the bolts up and "nip" the wheel to the hub.

4. When you have all the wheels back on and the car back on the ground, apply the handbrake and select P if it's an Auto.

Remove the chocks from the front wheel.

and then all that is left is to torque up the wheel bolts.

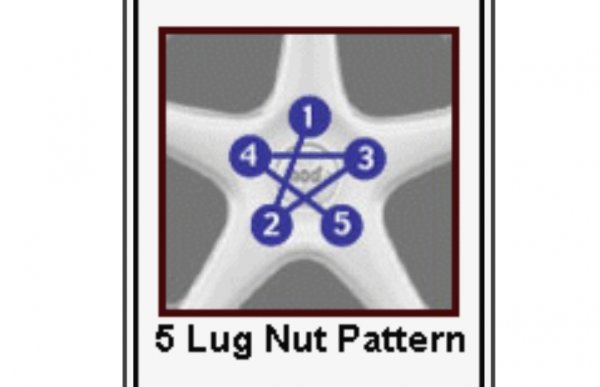

5. To torque up the bolts you have to set the wrench to the applicable figure for the vehicle you're working on. In this case 120nm. Something kindly pointed out by @Jack Ratt when tightening a 5 bolt pattern I tighten one, then skip one, working my way round the wheel.

when tightening a 5 bolt pattern I tighten one, then skip one, working my way round the wheel.

I set the wrench horizontal to start with, after I applied the correct torque the wrench had moved approx. 15 degrees below horizontal, indicating the the bolts had turned.

If you use the impact wrench any higher than the low setting the wheel bolt will already be "over tightened".

I can show this by moving the wrench to the next bolt. When placing the torque wrench horizontal and applying the correct torque the wrench does not move from the horizontal position, meaning that the bolt is already too tight. nb. After use the torque wrench should be de adjusted back to zero for storage - you should not leave a torque wrench under tension for long periods of time.

Hope this is helpful and if you have a question please ask.

Tony.

ps. Next time you have tyres fitted please pay particular attention to the person tightening your wheel bolts. IF the torque wrench does not move, it is already too tight. If wheel bolts are tightened to the correct torque the tool supplied with the car is adequate to loosen the fixings. If you see this happening, go and complain and ask for it to be correctly.

pps. I almost forgot one important detail, please make sure your wheel centre caps are correctly aligned with the valve stem. Apologies fir the dirty valve caps @andyglym , speed limiter is on.

1. I use a long "stud" to aid with locating the wheel onto the hub. This has a slot cut in the end to facilitate removal if it's a bit tight to turn.

2. Next, I use a short extension and socket to screw in the bolts, again much easier than using just your finger and thumb.

3. Next I use my impact wrench on the lowest setting (1 on my Ryobi tool) to run the bolts up and "nip" the wheel to the hub.

4. When you have all the wheels back on and the car back on the ground, apply the handbrake and select P if it's an Auto.

Remove the chocks from the front wheel.

and then all that is left is to torque up the wheel bolts.

5. To torque up the bolts you have to set the wrench to the applicable figure for the vehicle you're working on. In this case 120nm. Something kindly pointed out by @Jack Ratt

when tightening a 5 bolt pattern I tighten one, then skip one, working my way round the wheel.

when tightening a 5 bolt pattern I tighten one, then skip one, working my way round the wheel.I set the wrench horizontal to start with, after I applied the correct torque the wrench had moved approx. 15 degrees below horizontal, indicating the the bolts had turned.

If you use the impact wrench any higher than the low setting the wheel bolt will already be "over tightened".

I can show this by moving the wrench to the next bolt. When placing the torque wrench horizontal and applying the correct torque the wrench does not move from the horizontal position, meaning that the bolt is already too tight. nb. After use the torque wrench should be de adjusted back to zero for storage - you should not leave a torque wrench under tension for long periods of time.

Hope this is helpful and if you have a question please ask.

Tony.

ps. Next time you have tyres fitted please pay particular attention to the person tightening your wheel bolts. IF the torque wrench does not move, it is already too tight. If wheel bolts are tightened to the correct torque the tool supplied with the car is adequate to loosen the fixings. If you see this happening, go and complain and ask for it to be correctly.

pps. I almost forgot one important detail, please make sure your wheel centre caps are correctly aligned with the valve stem. Apologies fir the dirty valve caps @andyglym , speed limiter is on.

Last edited: