Need help with exhaust flange bolts on 3.0L!!

- Thread starter harvey210

- Start date

Hi

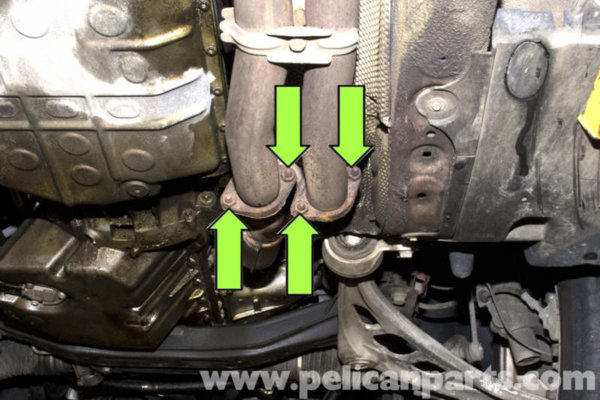

If original, the nuts should be made of copper. The studs are made of a special hard metal and are pressed into the upper flange.

Removing the nuts are a carefully, slowly job. Try lots of penetrating oil and leave it over night to soak in. If they don't want to come off you can try a nut spliter or file the nut face to release the joint. Trying to keep the thread and stud in good condition as they are hard to replace. Refrain from the temptation of hitting them with a hammer as the vibrations often damage the O2 sensors.

If original, the nuts should be made of copper. The studs are made of a special hard metal and are pressed into the upper flange.

Removing the nuts are a carefully, slowly job. Try lots of penetrating oil and leave it over night to soak in. If they don't want to come off you can try a nut spliter or file the nut face to release the joint. Trying to keep the thread and stud in good condition as they are hard to replace. Refrain from the temptation of hitting them with a hammer as the vibrations often damage the O2 sensors.

The studs will knock out of the flange (you can make it easier by applying some heat) then you can replace them with nuts and bolts.

Tony.

Tony.

This is probably the worst job possible to tackle on a Z3. This is why the Zedshed cut exhaust systems in 2 when they do rear axles.

The bolts are splined and almost weld themselves to the holes. The whole flange deteriorates over time too and could be wasted when you remove it.

They will come out with heat but it needs a lot of it from a proper torch and not a DIY thing.

And the bolts probably won’t be reusable.

I have a way of doing it when the assembly is out of the car as I removed an engine with half of the exhaust system still attached to the manifold. You cut a relief slot with an angle grinder to the outside of the bolt. This allows the stud itself to create some wriggle room as you punch it through. No heat required. Haven’t yet tried it in situ and not sure if there is room for the grinder. When reassembling it has no impact on the gas seal.

Search for my 2.2 engine replacement thread for pictures.

The ultimate answer is to buy replacement flange assemblies. Get these welded on first. Then they are easy to dismantle immediately afterwards. That’s what I’m going to do next time.

One member had this done by a garage Bridgnorth way I think. Very neat and about £250.

You really are almost certainly wasting your time with asking the bolts nicely if they’d like to come out

The bolts are splined and almost weld themselves to the holes. The whole flange deteriorates over time too and could be wasted when you remove it.

They will come out with heat but it needs a lot of it from a proper torch and not a DIY thing.

And the bolts probably won’t be reusable.

I have a way of doing it when the assembly is out of the car as I removed an engine with half of the exhaust system still attached to the manifold. You cut a relief slot with an angle grinder to the outside of the bolt. This allows the stud itself to create some wriggle room as you punch it through. No heat required. Haven’t yet tried it in situ and not sure if there is room for the grinder. When reassembling it has no impact on the gas seal.

Search for my 2.2 engine replacement thread for pictures.

The ultimate answer is to buy replacement flange assemblies. Get these welded on first. Then they are easy to dismantle immediately afterwards. That’s what I’m going to do next time.

One member had this done by a garage Bridgnorth way I think. Very neat and about £250.

You really are almost certainly wasting your time with asking the bolts nicely if they’d like to come out

A reciprocating saw with a metal cutting saw would probably work well for the studs you can't get an angle grinder or cut off tool to Rob?

Tony.

ps. Yes you do need to get the flange cherry red to punch the studs out easily.

Tony.

ps. Yes you do need to get the flange cherry red to punch the studs out easily.

See page 4 for relief slot method. And just how wasted the studs and flanges get.

https://zroadster.org/threads/2-2-engine-replacement-project.17379/

I’ll see if I can find the replacement welded flange thread now.

https://zroadster.org/threads/2-2-engine-replacement-project.17379/

I’ll see if I can find the replacement welded flange thread now.

Last edited:

Quite possibly. Although you may only get the tip on it and it might vibrate too much at that point.A reciprocating saw with a metal cutting saw would probably work well for the studs you can't get an angle grinder or cut off tool to Rob?

Tony.

ps. Yes you do need to get the flange cherry red to punch the studs out easily.

Flange replacement. Lovely solution to the problem both for removal and for future.

https://zroadster.org/threads/2-2-exhaust-repair.22763/

https://zroadster.org/threads/2-2-exhaust-repair.22763/

Just to clarify we've only done this to a couple of cars, we don't do it anymore as you can remove the subframe without removing the exhaust.This is probably the worst job possible to tackle on a Z3. This is why the Zedshed cut exhaust systems in 2 when they do rear axles.

The bolts are splined and almost weld themselves to the holes. The whole flange deteriorates over time too and could be wasted when you remove it.

They will come out with heat but it needs a lot of it from a proper torch and not a DIY thing.

And the bolts probably won’t be reusable.

I have a way of doing it when the assembly is out of the car as I removed an engine with half of the exhaust system still attached to the manifold. You cut a relief slot with an angle grinder to the outside of the bolt. This allows the stud itself to create some wriggle room as you punch it through. No heat required. Haven’t yet tried it in situ and not sure if there is room for the grinder. When reassembling it has no impact on the gas seal.

Search for my 2.2 engine replacement thread for pictures.

The ultimate answer is to buy replacement flange assemblies. Get these welded on first. Then they are easy to dismantle immediately afterwards. That’s what I’m going to do next time.

One member had this done by a garage Bridgnorth way I think. Very neat and about £250.

You really are almost certainly wasting your time with asking the bolts nicely if they’d like to come out

You just hang the exhaust down now and take the axle assembly out sideways past it?Just to clarify we've only done this to a couple of cars, we don't do it anymore as you can remove the subframe without removing the exhaust.

In a fashion yeah, we take each swing arm out with drive shaft and then drop the subframe with diff on its own. Little bit longer but saves having to disturb those crusty exhaust flanges.You just hang the exhaust down now and take the axle assembly out sideways past it?

It may be cheating, but we have an old fashioned independant garage workshop in the village. Having decided the nuts were on too tight for me to shift I took it to him and asked for some help. I think he charged £10 which was well worth it. I think he used heat and a heavy duty air gun. The replacement nuts should be copper plated and are readily available from ebay.

I’m doing my first one now, well apart from the breakers where the exhaust wasn’t a consideration. And I was going to remove the whole thing piecemeal. All 4 trailing arm bolts are all undone and ready to come off. I think I must have spent 2-3 hours on them. So with that thought I’ll save myself a little time and have the beam/diff out together.In a fashion yeah, we take each swing arm out with drive shaft and then drop the subframe with diff on its own. Little bit longer but saves having to disturb those crusty exhaust flanges.

Hopefully @harvey210 you can see the exhaust is something that beats most of us. And one way or another is something best left to the professionals. Who by the way will also struggle to remove the studs but that’s their problem. All things considered the replacement flanges are a lovely solution if you know a proficient welder.