So, for some reason, I wanted to put nice, actual-flowing headers on the Z3

Bear in mind: it’s a Z3 3.0/M54 roadster with an auto trans. There’s a ton of posts out there, and videos, but not many specifically about the Z3 / 3.0 / auto trans.

I purchased the headers that look like this:

The idea was that I would use an DME from Revmatch with the post cat sensors and PAIR / SAP delete. (For off Road purposes only.)

here are my discoveries:

there is a YouTube video that states, due to the OEM bolt pattern, you will (MUST) drill and tap the head for additional studs, or it will leak. For that reason I bought The headers with a complete, uncut, flange. (The same style as OEM, with the idea that if the flange is square stock and thick enough, it cannot heat-warp enough to leak)

Reality one: the reason a lot of these are leaking is not because of the bolt pattern. The headers themselves from eBay had such badly warped flanges that there is no way would have NOT leaked. I spent about four hours with 80 grit sandpaper and a large chunk of granite countertop scrap wet sanding/decking the header flange until it was damn near a perfect plane.

Reality two: the M 54 head is already pre-drilled for 24 exhaust flange bolts. (Yay) The local hardware store had a supply of 7 x 1 mm grade 8 bolts that was just enough for me to fill every hole.

I was able to do the entire header swap in the garage, using a floor jack to support the engine while the brace was removed. If you want to do this and you do not have a 90° electric ratchet wrench, it will be miserable. You will be miserable.

Now, Let’s talk about the automatic transmission.

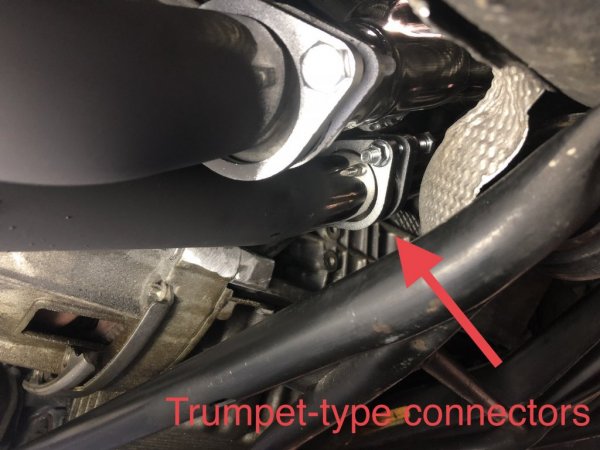

The bell housing is larger than the manual transmission. Due to the arrangement of the headers, in the arrangement of all the available headers except actual quality ones, I did have to grind a small portion of the transmission bell housing flange in order to gain clearance for the exhaust connector.

Reality three: the stock exhaust tubes that go from the headers to the resonator are different sizes. One appears to be 50 mm, or just under 2 inches, the other is just over 2 inches, approximately 2.15 inches outside diameter. The larger pipe will perfectly slip fit a 2 inch OD pipe. Fortunately, with the amount of larger pipe I was able to cut off and salvage it made the perfect coupling for the smaller pipe which is almost equivalent to 2 inches. No additional couplings had to be bought.

I am able to weld with my crappy easy bake oven wire feed welder so that wasn’t a problem. I would not recommend using any type of clamp. (Measure twice, cut once.)

at the end of the day working by myself, I would say it took an entire day’s work including some setbacks to install the headers. I don’t have a sound clip of the exhaust before and after but the exhaust after sounds fantastic without being too loud. (Im

Old)

The rear O2 sensors are removed from the system and the plugs are just clipped into their spots on top of the engine. The SAP pump can be reinstalled and operates normally. It may be removed at a later date.

For surethis is a prime example of when the mechanic slept with the engineers wife, and this vehicle is 100% the engineers revenge.

I know any performance gains, even with a tune will be moderate at best. However, the car sounds much more alive and it was a fun project. I did not take photos during the process, I should have, but I have attached photos attempting to describe what I have explained here.

Feel free to ask any questions!

Bear in mind: it’s a Z3 3.0/M54 roadster with an auto trans. There’s a ton of posts out there, and videos, but not many specifically about the Z3 / 3.0 / auto trans.

I purchased the headers that look like this:

The idea was that I would use an DME from Revmatch with the post cat sensors and PAIR / SAP delete. (For off Road purposes only.)

here are my discoveries:

there is a YouTube video that states, due to the OEM bolt pattern, you will (MUST) drill and tap the head for additional studs, or it will leak. For that reason I bought The headers with a complete, uncut, flange. (The same style as OEM, with the idea that if the flange is square stock and thick enough, it cannot heat-warp enough to leak)

Reality one: the reason a lot of these are leaking is not because of the bolt pattern. The headers themselves from eBay had such badly warped flanges that there is no way would have NOT leaked. I spent about four hours with 80 grit sandpaper and a large chunk of granite countertop scrap wet sanding/decking the header flange until it was damn near a perfect plane.

Reality two: the M 54 head is already pre-drilled for 24 exhaust flange bolts. (Yay) The local hardware store had a supply of 7 x 1 mm grade 8 bolts that was just enough for me to fill every hole.

I was able to do the entire header swap in the garage, using a floor jack to support the engine while the brace was removed. If you want to do this and you do not have a 90° electric ratchet wrench, it will be miserable. You will be miserable.

Now, Let’s talk about the automatic transmission.

The bell housing is larger than the manual transmission. Due to the arrangement of the headers, in the arrangement of all the available headers except actual quality ones, I did have to grind a small portion of the transmission bell housing flange in order to gain clearance for the exhaust connector.

Reality three: the stock exhaust tubes that go from the headers to the resonator are different sizes. One appears to be 50 mm, or just under 2 inches, the other is just over 2 inches, approximately 2.15 inches outside diameter. The larger pipe will perfectly slip fit a 2 inch OD pipe. Fortunately, with the amount of larger pipe I was able to cut off and salvage it made the perfect coupling for the smaller pipe which is almost equivalent to 2 inches. No additional couplings had to be bought.

I am able to weld with my crappy easy bake oven wire feed welder so that wasn’t a problem. I would not recommend using any type of clamp. (Measure twice, cut once.)

at the end of the day working by myself, I would say it took an entire day’s work including some setbacks to install the headers. I don’t have a sound clip of the exhaust before and after but the exhaust after sounds fantastic without being too loud. (Im

Old)

The rear O2 sensors are removed from the system and the plugs are just clipped into their spots on top of the engine. The SAP pump can be reinstalled and operates normally. It may be removed at a later date.

For surethis is a prime example of when the mechanic slept with the engineers wife, and this vehicle is 100% the engineers revenge.

I know any performance gains, even with a tune will be moderate at best. However, the car sounds much more alive and it was a fun project. I did not take photos during the process, I should have, but I have attached photos attempting to describe what I have explained here.

Feel free to ask any questions!

Attachments

-

121.7 KB Views: 28

-

177.5 KB Views: 29

-

99.4 KB Views: 28

-

67.3 KB Views: 32

-

98.6 KB Views: 32

-

81.6 KB Views: 31

Last edited: